AUTOMOTIVE APPLICATIONS

Thin film Precision resistor 0.01%, TC2ppm, wirebondale, Anti-Crossive, MELF. Current sensing, Metal...

Read MoreMultilayer chip bead that is for EMI protection , Low DC resistance, high soldering heat resistance , muliple size availability for all kind of 4C applications, various electronics euqipments.

CBM Series±25% 0.5 Ω 100Ω 200mA

| Tolerance | Test Condition | DCR (Ω) max. | Impedance(Ω) | Rated Current (mA) max. |

|---|---|---|---|---|

| ±25% | 100MHz | 0.5 | 100 | 200 |

Electrical Performance Test

| Item | Specification | Test Method |

|---|---|---|

| Impedance | Refer to standard electrical spec. | HP4286A |

| DCR | HP 4338 digital mili-ohm meter |

Mechanical Performance Test

| Item | Specification | Test Method |

|---|---|---|

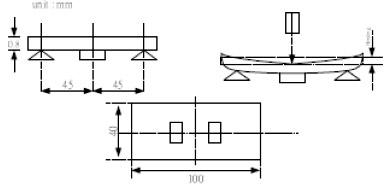

| Substrate Bending Test | Without deformation cases Impedance: within ± 30% of initial value DC Resistance shall be satisfied | Test device shall be soldered on the substrate Substrate Dimension: 100 x 40 x 0.8mm Deflection: 3.0mm Keeping Time: 10sec and then return  |

| Vibration | Appearance: No damage Impedance: within ± 30% of initial value DC Resistance shall be satisfied | Test device shall be soldered on the substrate Oscillation Frequency: 10 to 55 to 10Hz for 1min Amplitude: 1.5mm (peak-peak) Time: 2hrs for each axis (X, Y & Z), total 6hrs |

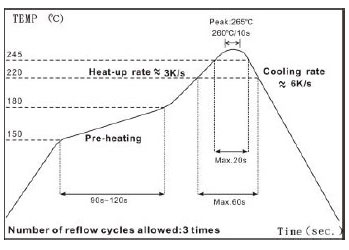

| Resistance to Soldering Heat | No visible damage Electrical characteristics and mechanical characteristics shall be satisfied | Solder temp: 265 ± 5°C Immersion time: 6 ± 1sec Preheating: 100°C to 150°C, 1 minute Measured after exposure in the room condition for 24hrs Solder: Sn-3Ag-0.5Cu |

| Solderability | 95% min. coverage of all metabolized area | Solder Temperature: 240 ± 5°C Immersion Time: 3 ± 1sec Solder: Sn-3Ag-0.5Cu |

| Terminal Strength | Without deformation cases Impedance: within ± 30% of initial value DC Resistance shall be satisfied | Solder chip on PCB and applied 10N (1.02Kgf) for 10 sec |

| Temperature Cycle | Appearance: No damage Impedance: within ± 30% of initial value DC Resistance shall be satisfied | One cycle: One cycle/step1: -55 ± 3°C for 30 ± 3min step2: standard atmospheric conditions 5s or less step3:125 ± 2°C for 30 ± 3min step4: standard atmospheric conditions 5s or less Total: 100cycles Measured after exposure in the room condition for 24hrs |

| Humidity Resistance | Temperature: 60 ± 2°C Relative Humidity: 90 ~ 95% Applied Current: Rated Current(maximum value) Time: 1008 ± 12hrs Measured after exposure in the room condition for 24hrs | |

| High Temperature Resistance | Temperature: 125 ± 2°C Applied Current: Rated Current(maximum value) Time: 1008 ± 12hrs Measured after exposure in the room condition for 24hrs | |

| Low Temperature Storage Life Test | Temperature: -55 ± 2°C Time: 1008 ± 12hrs Measured after exposure in the room condition for 24hrs | |

| Thermal Shock | -55°C ~ 125°C kept stabilized for 30 minutes each for 100 cycles Measured after exposure in the room condition for 24hrs |

☑ Operating Temperature: -55°C ~ 125°C

☑ Storage Temperature: 15 ~ 28°C ; Humidity < 80%RH

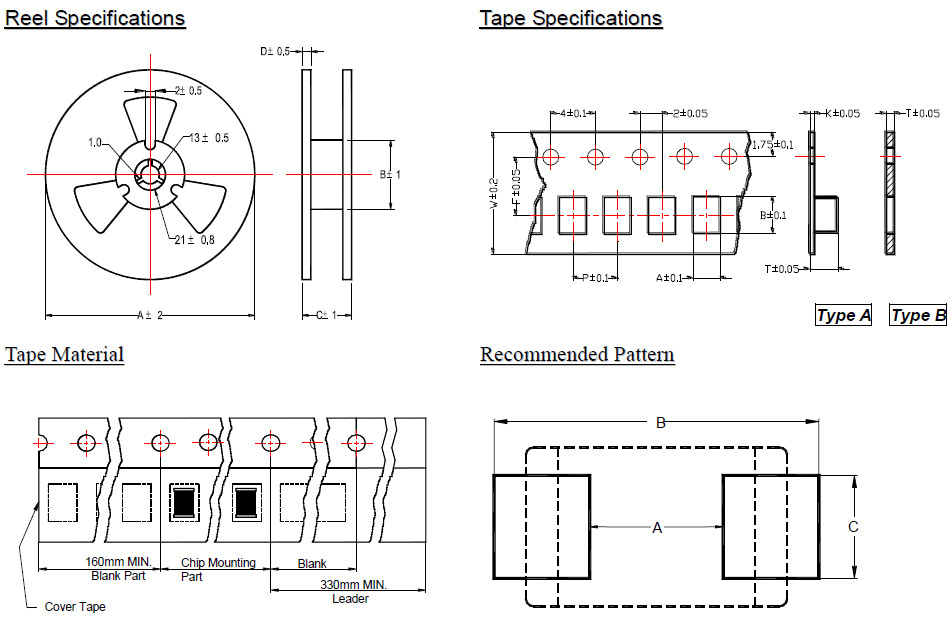

| Type | Tape Dimensions | Reel Dimensions | Recommended Pattern | Quantity (EA) | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| A | B | T | W | P | F | K | Tape Type | A | B | C | D | A | B | C | ||

| CBM01 | 0.38 | 0.68 | 1.10 | 8.0 | 2.0 | 3.5 | - | B | 178 | 60 | 10 | 2 | 0.25 | 0.69 | 0.32 | 15000 |

| CBM02 | 0.65 | 1.15 | 0.80 | 8.0 | 2.0 | 3.5 | - | B | 178 | 60 | 10 | 2 | 0.50 | 2.10 | 0.55 | 10000 |

| CBM03 | 1.10 | 1.90 | 1.10 | 8.0 | 4.0 | 3.5 | - | B | 178 | 60 | 10 | 2 | 0.60 | 2.60 | 0.80 | 4000 |

| CBM05 | 1.55 | 2.30 | 1.20 | 8.0 | 4.0 | 3.5 | - | B | 178 | 60 | 10 | 2 | 0.66 | 3.23 | 1.47 | 4000 |

| CBM04 | 1.90 | 3.50 | 1.40 | 8.0 | 4.0 | 3.5 | 0.2 | A | 178 | 60 | 10 | 2 | 2.20 | 4.40 | 2.06 | 3000 |

| CBM10 | 2.90 | 3.60 | 1.70 | 8.0 | 4.0 | 3.5 | 0.2 | A | 178 | 60 | 10 | 2 | 2.13 | 4.06 | 2.74 | 2000 |

| CBM08 | 2.90 | 4.90 | 1.40 | 12 | 4.0 | 5.5 | 0.3 | A | 178 | 60 | 14 | 2 | 2.70 | 5.70 | 2.24 | 2000 |

| CBM12 | 3.60 | 4.90 | 2.05 | 12 | 8.0 | 5.5 | 0.3 | A | 178 | 60 | 14 | 2 | 2.57 | 5.90 | 4.22 | 1000 |

| CBM20 | 5.40 | 5.95 | 3.42 | 12 | 8.0 | 5.5 | 0.33 | A | 330 | 100 | 14.5 | 2 | 3.05 | 9.19 | 6.1 | 2000 |

Thin film Precision resistor 0.01%, TC2ppm, wirebondale, Anti-Crossive, MELF. Current sensing, Metal...

Read More

Ceramic high frequency chip inductors, small size to 01005. Thin film, multilayer, wirewound , ferrite...

Read More

Multilayer Ceramic capacitor offers high Voltage, high frequency, low noise, High Q, Low TCR. NPO, X7R,...

Read More