AUTOMOBILANWENDUNGEN

Dünnschicht-Präzisionswiderstand 0,01%, TC2ppm, Drahtbondable, Antikorrosiv, MELF. Stromsensoren, Metall,...

WeiterlesenMehrschicht-Keramik-Chip-Induktor, Hochfrequenz-, RF-Induktor für hohe SRF, ausgezeichnete Q, überlegbare Temperaturstabilität. Stabile Induktivität in Hochfrequenzschaltungen. Hochstabile Konstruktion für kritische Anforderungen.

CL Series0603 ±5%nH 330nHμH 2.8 Ω 150mA 8 0.35GHz

| Größe | Toleranz | Induktivität | Testbedingungen | DCR (Ω) max. | IDC (mA) | Q | SRF |

|---|---|---|---|---|---|---|---|

| 0603 | ±5% | 330nH | 50MHz | 2.8 | 150 | 8 | 0.35GHz |

CL01-S Multilayer Chip Inductors / High Q Type

| Inductance (nH) | Tolerance | Quality Factor /min. | Test Freq. (MHz) | Test Voltage (mV) | SRF (GHz) min. | RDC (Ω) max. | IDC (mA) max. |

|---|---|---|---|---|---|---|---|

| 0.6 | ± 0.1nH, ± 0.2nH, ± 0.3nH | 14 | 500 | 50 | 10.00 | 0.05 | 1000 |

| 0.7 | ± 0.1nH, ± 0.2nH, ± 0.3nH | 14 | 500 | 50 | 10.00 | 0.05 | 1000 |

| 0.8 | ± 0.1nH, ± 0.2nH, ± 0.3nH | 14 | 500 | 50 | 10.00 | 0.06 | 1000 |

| 0.9 | ± 0.1nH, ± 0.2nH, ± 0.3nH | 14 | 500 | 50 | 10.00 | 0.06 | 800 |

| 1.0 | ± 0.1nH, ± 0.2nH, ± 0.3nH | 14 | 500 | 50 | 10.00 | 0.07 | 800 |

| 1.1 | ± 0.1nH, ± 0.2nH, ± 0.3nH | 14 | 500 | 50 | 10.00 | 0.07 | 800 |

| 1.2 | ± 0.1nH, ± 0.2nH, ± 0.3nH | 14 | 500 | 50 | 10.00 | 0.10 | 800 |

| 1.3 | ± 0.1nH, ± 0.2nH, ± 0.3nH | 14 | 500 | 50 | 10.00 | 0.10 | 700 |

| 1.4 | ± 0.1nH, ± 0.2nH, ± 0.3nH | 14 | 500 | 50 | 10.00 | 0.10 | 700 |

| 1.5 | ± 0.1nH, ± 0.2nH, ± 0.3nH | 14 | 500 | 50 | 10.00 | 0.10 | 650 |

| 1.6 | ± 0.1nH, ± 0.2nH, ± 0.3nH | 14 | 500 | 50 | 10.00 | 0.10 | 650 |

| 1.7 | ± 0.1nH, ± 0.2nH, ± 0.3nH | 14 | 500 | 50 | 10.00 | 0.10 | 650 |

| 1.8 | ± 0.1nH, ± 0.2nH, ± 0.3nH | 14 | 500 | 50 | 9.00 | 0.15 | 650 |

| 2.0 | ± 0.1nH, ± 0.2nH, ± 0.3nH | 14 | 500 | 50 | 8.50 | 0.15 | 650 |

| 2.2 | ± 0.1nH, ± 0.2nH, ± 0.3nH | 14 | 500 | 50 | 7.50 | 0.15 | 650 |

| 2.4 | ± 0.1nH, ± 0.2nH, ± 0.3nH | 14 | 500 | 50 | 7.50 | 0.15 | 550 |

| 2.6 | ± 0.1nH, ± 0.2nH, ± 0.3nH | 14 | 500 | 50 | 7.50 | 0.20 | 550 |

| 2.7 | ± 0.1nH, ± 0.2nH, ± 0.3nH | 14 | 500 | 50 | 7.50 | 0.20 | 550 |

| 2.8 | ± 0.1nH, ± 0.2nH, ± 0.3nH | 14 | 500 | 50 | 7.50 | 0.20 | 500 |

| 3.0 | ± 0.1nH, ± 0.2nH, ± 0.3nH | 14 | 500 | 50 | 7.50 | 0.20 | 450 |

| 3.3 | ± 0.1nH, ± 0.2nH, ± 0.3nH | 14 | 500 | 50 | 7.50 | 0.25 | 450 |

| 3.6 | ± 0.1nH, ± 0.2nH, ± 0.3nH | 14 | 500 | 50 | 6.50 | 0.25 | 400 |

| 3.9 | ± 0.1nH, ± 0.2nH, ± 0.3nH | 14 | 500 | 50 | 6.50 | 0.25 | 400 |

| 4.3 | ± 0.1nH, ± 0.2nH, ± 0.3nH | 14 | 500 | 50 | 6.00 | 0.35 | 350 |

| 4.7 | ± 0.1nH, ± 0.2nH, ± 0.3nH | 14 | 500 | 50 | 6.00 | 0.40 | 350 |

| 5.1 | ± 0.1nH, ± 0.2nH, ± 0.3nH | 14 | 500 | 50 | 5.50 | 0.40 | 350 |

| 5.6 | ± 0.1nH, ± 0.2nH, ± 0.3nH | 14 | 500 | 50 | 5.00 | 0.40 | 350 |

| 6.2 | ± 0.1nH, ± 0.2nH, ± 0.3nH | 14 | 500 | 50 | 5.00 | 0.40 | 300 |

| 6.8 | ± 3%, ± 5% | 14 | 500 | 50 | 4.50 | 0.50 | 300 |

| 7.5 | ± 3%, ± 5% | 14 | 500 | 50 | 4.00 | 0.50 | 300 |

| 8.2 | ± 3%, ± 5% | 14 | 500 | 50 | 4.00 | 0.50 | 250 |

| 9.1 | ± 3%, ± 5% | 14 | 500 | 50 | 4.00 | 0.70 | 250 |

| 10 | ± 3%, ± 5% | 14 | 500 | 50 | 4.00 | 0.70 | 250 |

| 12 | ± 3%, ± 5% | 13 | 500 | 50 | 3.50 | 0.70 | 250 |

| 15 | ± 3%, ± 5% | 13 | 500 | 50 | 3.20 | 0.85 | 250 |

| 18 | ± 3%, ± 5% | 13 | 500 | 50 | 3.00 | 1.00 | 200 |

| 20 | ± 3%, ± 5% | 13 | 500 | 50 | 2.20 | 1.10 | 150 |

| 22 | ± 3%, ± 5% | 13 | 500 | 50 | 2.20 | 1.20 | 150 |

| 27 | ± 3%, ± 5% | 13 | 500 | 50 | 2.20 | 1.50 | 140 |

| 33 | ± 3%, ± 5% | 12 | 300 | 50 | 1.80 | 1.80 | 120 |

| 36 | ± 3%, ± 5% | 12 | 300 | 50 | 1.70 | 2.00 | 120 |

| 39 | ± 3%, ± 5% | 12 | 300 | 50 | 1.60 | 2.00 | 100 |

| 43 | ± 3%, ± 5% | 12 | 300 | 50 | 1.60 | 2.20 | 100 |

| 47 | ± 3%, ± 5% | 12 | 300 | 50 | 1.50 | 2.20 | 100 |

| 56 | ± 3%, ± 5% | 12 | 300 | 50 | 1.20 | 2.50 | 100 |

| 68 | ± 3%, ± 5% | 12 | 300 | 50 | 1.00 | 3.20 | 120 |

| 75 | ± 3%, ± 5% | 11 | 300 | 50 | 1.00 | 3.60 | 100 |

| 82 | ± 3%, ± 5% | 11 | 300 | 50 | 1.00 | 3.80 | 100 |

| 91 | ± 3%, ± 5% | 11 | 300 | 50 | 0.90 | 3.80 | 80 |

| 100 | ± 3%, ± 5% | 11 | 300 | 50 | 0.80 | 4.00 | 80 |

| 120 | ± 3%, ± 5% | 10 | 300 | 50 | 0.80 | 5.00 | 80 |

☑ Operating temperature range: -55 ~ +125°C

CL02-S Multilayer Chip Inductors / High Q Type

| Inductance (nH) | Tolerance | Quality Factor /min. | L/Q Freq. (MHz) | Q (Typical) Freq. (MHz) | SRF (GHz) Min. | RDC (Ω) Max. | IDC (mA) Max. | |||

|---|---|---|---|---|---|---|---|---|---|---|

| 100 | 250 | 900 | 180 | |||||||

| 1.0 | ± 0.1nH, ± 0.2nH, ± 0.3nH | 20 | 250 | 13 | 22 | 48 | 75 | 6.00 | 0.05 | 1000 |

| 1.2 | ± 0.1nH, ± 0.2nH, ± 0.3nH | 20 | 250 | 13 | 22 | 48 | 75 | 6.00 | 0.05 | 1000 |

| 1.5 | ± 0.1nH, ± 0.2nH, ± 0.3nH | 20 | 250 | 13 | 22 | 58 | 76 | 6.00 | 0.05 | 1000 |

| 1.8 | ± 0.1nH, ± 0.2nH, ± 0.3nH | 20 | 250 | 13 | 22 | 49 | 78 | 6.00 | 0.07 | 800 |

| 2.0 | ± 0.1nH, ± 0.2nH, ± 0.3nH | 20 | 250 | 14 | 23 | 49 | 82 | 6.00 | 0.07 | 800 |

| 2.2 | ± 0.1nH, ± 0.2nH, ± 0.3nH | 20 | 250 | 14 | 23 | 49 | 82 | 6.00 | 0.07 | 800 |

| 2.4 | ± 0.1nH, ± 0.2nH, ± 0.3nH | 20 | 250 | 14 | 23 | 47 | 78 | 6.00 | 0.07 | 800 |

| 2.5 | ± 0.1nH, ± 0.2nH, ± 0.3nH | 20 | 250 | 14 | 23 | 47 | 78 | 6.00 | 0.07 | 800 |

| 2.7 | ± 0.1nH, ± 0.2nH, ± 0.3nH | 20 | 250 | 14 | 23 | 48 | 82 | 6.00 | 0.09 | 700 |

| 2.9 | ± 0.1nH, ± 0.2nH, ± 0.3nH | 20 | 250 | 14 | 23 | 48 | 82 | 6.00 | 0.09 | 700 |

| 3.0 | ± 0.1nH, ± 0.2nH, ± 0.3nH | 20 | 250 | 14 | 23 | 50 | 84 | 6.00 | 0.09 | 700 |

| 3.3 | ± 0.1nH, ± 0.2nH, ± 0.3nH | 20 | 250 | 14 | 24 | 52 | 90 | 6.00 | 0.09 | 700 |

| 3.6 | ± 0.1nH, ± 0.2nH, ± 0.3nH | 20 | 250 | 15 | 24 | 55 | 95 | 6.00 | 0.10 | 700 |

| 3.9 | ± 0.1nH, ± 0.2nH, ± 0.3nH | 20 | 250 | 15 | 25 | 50 | 89 | 6.00 | 0.10 | 700 |

| 4.1 | ± 0.1nH, ± 0.2nH, ± 0.3nH | 20 | 250 | 15 | 25 | 49 | 86 | 6.00 | 0.12 | 650 |

| 4.3 | ± 0.1nH, ± 0.2nH, ± 0.3nH | 20 | 250 | 15 | 25 | 49 | 86 | 6.00 | 0.13 | 600 |

| 4.7 | ± 0.1nH, ± 0.2nH, ± 0.3nH | 20 | 250 | 15 | 26 | 50 | 88 | 6.00 | 0.13 | 600 |

| 5.1 | ± 0.1nH, ± 0.2nH, ± 0.3nH | 20 | 250 | 15 | 26 | 49 | 84 | 5.50 | 0.13 | 600 |

| 5.6 | ± 0.1nH, ± 0.2nH, ± 0.3nH | 20 | 250 | 15 | 27 | 50 | 84 | 5.50 | 0.13 | 600 |

| 5.8 | ± 0.1nH, ± 0.2nH, ± 0.3nH | 20 | 250 | 15 | 27 | 50 | 82 | 5.50 | 0.13 | 600 |

| 6.2 | ± 0.1nH, ± 0.2nH, ± 0.3nH | 20 | 250 | 15 | 27 | 50 | 80 | 5.50 | 0.14 | 550 |

| 6.8 | ± 2%, ± 3%, ± 5% | 22 | 250 | 15 | 27 | 55 | 89 | 5.00 | 0.15 | 550 |

| 7.3 | ± 2%, ± 3%, ± 5% | 22 | 250 | 15 | 27 | 54 | 90 | 5.00 | 0.16 | 550 |

| 7.5 | ± 2%, ± 3%, ± 5% | 22 | 250 | 15 | 27 | 54 | 90 | 5.00 | 0.16 | 550 |

| 8.2 | ± 2%, ± 3%, ± 5% | 22 | 250 | 15 | 27 | 56 | 84 | 5.00 | 0.16 | 550 |

| 8.7 | ± 2%, ± 3%, ± 5% | 22 | 250 | 15 | 27 | 53 | 80 | 5.00 | 0.17 | 500 |

| 9.1 | ± 2%, ± 3%, ± 5% | 22 | 250 | 15 | 27 | 53 | 79 | 4.50 | 0.18 | 500 |

| 9.5 | ± 2%, ± 3%, ± 5% | 22 | 250 | 15 | 27 | 52 | 77 | 4.50 | 0.18 | 500 |

| 10 | ± 2%, ± 3%, ± 5% | 22 | 250 | 16 | 29 | 52 | 75 | 4.50 | 0.18 | 500 |

| 11 | ± 2%, ± 3%, ± 5% | 22 | 250 | 16 | 28 | 52 | 71 | 4.00 | 0.20 | 500 |

| 12 | ± 2%, ± 3%, ± 5% | 22 | 250 | 16 | 29 | 51 | 68 | 4.00 | 0.20 | 500 |

| 15 | ± 2%, ± 3%, ± 5% | 22 | 250 | 16 | 29 | 50 | 60 | 4.00 | 0.22 | 430 |

☑ Operating temperature range: -55 ~ +125°C

CL02-S Multilayer Chip Inductors / High Frequency Type

| Inductance (nH) | Tolerance | Quality Factor /min. | L/Q Freq. (MHz) | Q (Typical) Freq. (MHz) | SRF min. (GHz) | RDC (Ω) max. | IDC (mA) max. | |||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 100 | 300 | 500 | 800 | 1000 | 1800 | |||||||

| 1.0 | ± 0.3nH | 5 | 100 | 9 | 16 | 20 | 25 | 28 | 31 | >8.50 | 0.10 | 500 |

| 1.2 | ± 0.3nH | 5 | 100 | 9 | 15 | 18 | 24 | 27 | 31 | >8.50 | 0.12 | 500 |

| 1.5 | ± 0.3nH | 5 | 100 | 7 | 12 | 16 | 20 | 21 | 29 | >8.50 | 0.15 | 500 |

| 1.8 | ± 0.3nH | 5 | 100 | 7 | 12 | 16 | 20 | 21 | 29 | >8.50 | 0.17 | 500 |

| 2.2 | ± 0.3nH | 5 | 100 | 7 | 12 | 16 | 20 | 21 | 30 | >8.50 | 0.17 | 500 |

| 2.7 | ± 0.3nH | 5 | 100 | 7 | 12 | 16 | 20 | 21 | 29 | >8.50 | 0.20 | 500 |

| 3.3 | ± 0.3nH | 5 | 100 | 7 | 12 | 15 | 19 | 20 | 27 | >8.50 | 0.22 | 400 |

| 3.9 | ± 0.3nH | 5 | 100 | 7 | 12 | 15 | 20 | 21 | 28 | 7.50 | 0.25 | 400 |

| 4.7 | ± 0.3nH | 5 | 100 | 7 | 12 | 15 | 19 | 20 | 27 | 6.50 | 0.28 | 400 |

| 5.6 | ± 0.3nH | 5 | 100 | 8 | 12 | 15 | 20 | 22 | 30 | 6.50 | 0.30 | 400 |

| 6.8 | ± 5%, ± 10% | 5 | 100 | 8 | 12 | 15 | 20 | 22 | 30 | 6.50 | 0.35 | 400 |

| 8.2 | ± 5%, ± 10% | 5 | 100 | 8 | 12 | 15 | 19 | 21 | 30 | 6.50 | 0.38 | 350 |

| 10 | ± 5%, ± 10% | 5 | 100 | 8 | 13 | 16 | 21 | 23 | 32 | 4.70 | 0.42 | 350 |

| 12 | ± 5%, ± 10% | 5 | 100 | 8 | 13 | 16 | 20 | 23 | 27 | 4.30 | 0.47 | 350 |

| 15 | ± 5%, ± 10% | 5 | 100 | 8 | 12 | 15 | 19 | 22 | 28 | 4.00 | 0.50 | 300 |

| 18 | ± 5%, ± 10% | 5 | 100 | 8 | 13 | 16 | 21 | 24 | 32 | 4.00 | 0.60 | 250 |

| 22 | ± 5%, ± 10% | 5 | 100 | 8 | 13 | 17 | 22 | 26 | 31 | 3.50 | 0.70 | 200 |

| 27 | ± 5%, ± 10% | 5 | 100 | 8 | 14 | 18 | 23 | 26 | 32 | 3.00 | 0.80 | 200 |

| 33 | ± 5%, ± 10% | 5 | 100 | 8 | 14 | 17 | 23 | 27 | 32 | 2.50 | 0.90 | 200 |

| 39 | ± 5%, ± 10% | 5 | 100 | 8 | 14 | 18 | 23 | 27 | 32 | 2.00 | 1.00 | 200 |

| 47 | ± 5%, ± 10% | 7 | 100 | 9 | 14 | 18 | 22 | 24 | 29 | 2.40 | 2.20 | 100 |

| 56 | ± 5%, ± 10% | 7 | 100 | 9 | 14 | 18 | 23 | 24 | 29 | 2.30 | 2.50 | 100 |

| 68 | ± 5%, ± 10% | 7 | 100 | 9 | 14 | 17 | 22 | 24 | 29 | 2.20 | 2.70 | 100 |

| 82 | ± 5%, ± 10% | 7 | 100 | 8 | 13 | 17 | 20 | 20 | 16 | 2.10 | 2.90 | 100 |

| 100 | ± 5%, ± 10% | 7 | 100 | 8 | 13 | 17 | 20 | 20 | 13 | 2.00 | 3.20 | 100 |

☑ Operating temperature range: -55~+125°C

CL03-S Multilayer Chip Inductors / High Frequency Type

| Inductance (nH) | Tolerance | Quality Factor /min. | L/Q Freq. (MHz) | Q (Typical) Freq. (MHz) | SRF min. (GHz) | RDC (Ω) max. | IDC (mA) max. | |||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 100 | 300 | 500 | 800 | 1000 | 1800 | |||||||

| 10 | ± 5% | 8 | 100 | 10 | 22 | 28 | 35 | 39 | 45 | >6.00 | 0.6 | 500 |

| 12 | ± 5% | 8 | 100 | 10 | 18 | 23 | 26 | 32 | 42 | 6.00 | 0.7 | 500 |

| 15 | ± 5% | 8 | 100 | 12 | 22 | 28 | 35 | 39 | 42 | 5.50 | 0.8 | 500 |

| 18 | ± 5% | 8 | 100 | 10 | 18 | 22 | 25 | 30 | 43 | 5.20 | 0.9 | 300 |

| 22 | ± 5% | 8 | 100 | 12 | 21 | 27 | 34 | 37 | 37 | 5.00 | 1.0 | 300 |

| 27 | ± 5% | 8 | 100 | 10 | 18 | 24 | 26 | 32 | 38 | 4.80 | 1.2 | 300 |

| 33 | ± 5% | 8 | 100 | 12 | 21 | 27 | 33 | 35 | 31 | 4.50 | 1.4 | 300 |

| 39 | ± 5% | 8 | 100 | 11 | 20 | 26 | 32 | 34 | 29 | 4.00 | 1.5 | 200 |

| 47 | ± 5% | 8 | 100 | 12 | 20 | 26 | 31 | 34 | 27 | 3.50 | 1.6 | 200 |

| 56 | ± 5% | 8 | 100 | 11 | 20 | 26 | 31 | 34 | 24 | 3.00 | 1.8 | 200 |

| 68 | ± 5% | 8 | 100 | 10 | 18 | 21 | 24 | 28 | 20 | 2.80 | 2.0 | 200 |

| 82 | ± 5% | 8 | 100 | 10 | 19 | 22 | 26 | 26 | 15 | 2.50 | 2.2 | 200 |

| 100 | ± 5% | 8 | 100 | 10 | 19 | 24 | 27 | 25 | - | 2.00 | 2.5 | 150 |

| 120 | ± 5% | 8 | 100 | 10 | 19 | 23 | 26 | 24 | - | 1.60 | 2.8 | 150 |

| 150 | ± 5% | 8 | 100 | 10 | 18 | 24 | 26 | 23 | - | 1.40 | 3.0 | 150 |

| 180 | ± 5% | 8 | 100 | 10 | 17 | 22 | 23 | - | - | 1.00 | 3.4 | 150 |

☑ Operating temperature range: -40~+85°C

Electrical Performance Test

| Item | Requirement | Test Condition |

|---|---|---|

| Inductance | In Within specified tolerance | Temperature: 20 ± 1°C Relative Humidity: 45 to 85%RH Atmospheric Pressure: 86 to 106kpa Measuring equipment and fixture: 0201: E991A+HP16197A 0402/0603: E991A + HP16192A Test Signal: -20dBm or 50mV Test compensation(for 0201 high Q): Product true value = test value + compensation value. for L < 3.6nH, compensation value is 0.25nH; for 3.6nH ≤ L<6.8nH, compensation value is 0.43nH; for 6.8 nH ≤ L<9.1nH, compensation value is 0.5nH; for 9.1 nH ≤ L<33nH, compensation value is 0.85nH; for L ≥ 33nH, compensation value is 0.85nH; |

| Q Value | In accordance with electrical specification | Temperature: 20 ± 1°C Relative Humidity: 45 to 85%RH Atmospheric Pressure: 86 to 106kpa |

| DC Resistance | In accordance with electrical specification | Temperature: 20 ± 1°C Relative Humidity: 45 to 85%RH Atmospheric Pressure: 86 to 106kpa Measuring equipment: HP 4338 |

Mechanical Characteristies Test

| Item | Requirement | Test Condition |

|---|---|---|

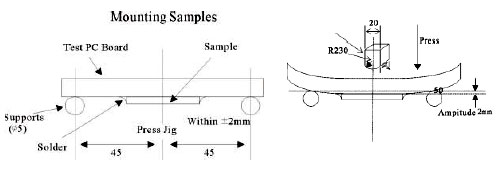

| Bending Strength | No mechanical damage shall be observed | Flexure: 2mm Pressurizing speed: 0.5mm/sec Keep time: 30sec  |

| Solderability | No visible mechanical damage Wetting shall exceed 75% coverage for 0201 series; exceed 95% coverage for others |

Solder temperature: 240 ± 2°C Time: 3 seconds Solder: Sn/3.0Ag/0.5Cu Flux: 25% resin and 75% ethanol in weight |

| Resistance to Soldering Heat | No visible mechanical damage Wetting shall exceed 75% coverage for 0201 series; exceed 95% coverage for others Inductance change: within ± 10% Q change: within ± 20% |

Solder temperature: 260 ± 3°C Time: 5 seconds Solder: Sn/3.0Ag/0.5Cu Flux: 25% resin and 75% ethanol in weight The chip shall be stabilized at normal condition for 1~2 hours before measuring |

| Dropping | No visible mechanical damage Inductance change: within ± 10% Q change: within ± 20% |

Drop chip inductor 10 times on a concrete floor form a height of 100cm |

Climatic Test

| Item | Requirement | Test Condition |

|---|---|---|

| Thermal Shock | No visible damage Inductance variation within 10% Q variation within 20% |

0201/0402 series: -55°C for 30 ± 3 min→125°C for 30 ± 3 min 0603 series: -40°C for 30 ± 3 min→85°C for 30 ± 3 min Transforming interval: max. 20 seconds Test cycle: 100 cycles The chip shall be stabilized at normal condition for 1~2 hours Before measuring |

| Resistance to Low Temperature | Temperature: 0201/0402 series: -55 ± 2°C; 0603 series: -40 ± 2°C Time: 1000 ± 24 hours The chip shall be stabilized at normal condition for 1~2 hours Before measuring |

|

| Resistance to High Temperature | Temperature: 0201/0402 series: 125 ± 2°C; 0603 series: 85 ± 2°C Time: 1000 ± 24 hours The chip shall be stabilized at normal condition for 1~2 hours Before measuring |

|

| Damp Heat (Steady States) | Temperature: 60 ± 2°C Humidity: 90 ~ 95% RH. Time: 1000 ± 24 hours The chip shall be stabilized at normal condition for 1~2 hours Before measuring |

|

| Loading Under Damp Heat | Temperature: 60 ± 2°C Humidity: 90~95% RH. Time: 1000 ± 24 hours Applied current: Rated current The chip shall be stabilized at normal condition for 1~2 hours Before measuring |

|

| Loading at High Temperature (Life Test) | Temperature: 0201/0402 series: 125 ± 2°C; 0603 series: 85 ± 2°C Time: 1000 ± 24 hours Applied current: Rated current The chip shall be stabilized at normal condition for 1~2 hours Before measuring |

☑ Storage Temperature: 15 ~ 28°C; Humidity < 80%RH

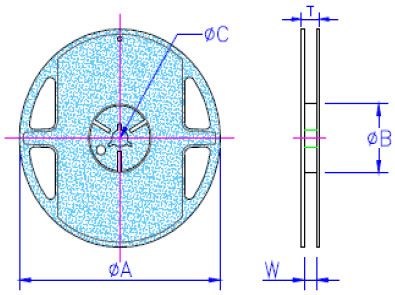

Reel Dimension (Unit : mm)

| Type | A | B | C | W | T | Quantity (EA) |  |

|---|---|---|---|---|---|---|---|

| CL01-S | 178 ± 1 | 60.0 ± 0.5 | 13.0 ± 0.20 | 9.00 ± 0.5 | 12.0 ± 0.15 | 15,000 | |

| CL02-S | 178 ± 1 | 57.0 ± 2 | 12.5 ± 1.50 | 8.00 +1.5/-0 | 12.0 ± 0.15 | 10,000 | |

| CL03-S | 178 ± 1 | 60.0 ± 0.5 | 13.0 ± 0.20 | 9.00 ± 0.5 | 12.0 ± 0.15 | 4,000 |

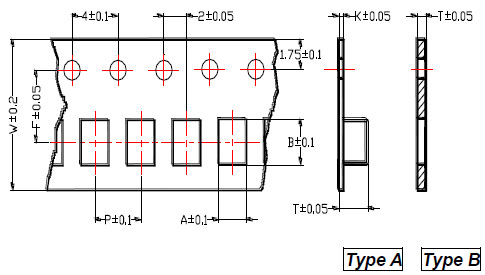

Tape Specifications (Unit : mm)

| Type | A | B | T | W | P | F | K | Tape |  |

|---|---|---|---|---|---|---|---|---|---|

| CL01-S | 0.40 | 0.70 | 0.50 | 8 | 2 | 3.5 | - | B | |

| CL02-S | 0.65 | 1.15 | 0.80 | 8 | 2 | 3.5 | - | B | |

| CL03-S | 1.10 | 1.80 | 1.10 | 8 | 4 | 3.5 | - | B |

Dünnschicht-Präzisionswiderstand 0,01%, TC2ppm, Drahtbondable, Antikorrosiv, MELF. Stromsensoren, Metall,...

Weiterlesen

Keramische Hochfrequenz-Chip-Induktoren, klein bis 01005. Dünnschicht-, Mehrschicht-, Drahtgewickelte-,...

Weiterlesen

Mehrschicht-Keramikkondensator bietet hohe Spannung, hohe Frequenz, geringes Rauschen, hohe Güte, niedrige...

Weiterlesen