AUTOMOTIVE APPLICATIONS

Thin film Precision resistor 0.01%, TC2ppm, wirebondale, Anti-Crossive, MELF. Current sensing, Metal...

Read MoreAutomotive Grade High Power Thin Film Chip Resistors - ARTP..A Series

ARTP..A Series0402 ±0.1% 25 1/5W Series154Ω 10K/Reel

| Size | Tolerance | TCR (ppm /℃) | Power | Resistance (Ohm) | Package |

|---|---|---|---|---|---|

| 0402 | ±0.1% | 25 | 1/5W | 154 | 10K/Reel |

| Item | Requirement | Test Method |

|---|---|---|

| Temperature Coefficient of Resistance (T.C.R.) | As Spec. | MIL-STD-202 Method 304 +25/-55/+25/+125/+25°C |

| Short Time Overload(Power operation mode) | Δ R± 0.25% | JIS-C-5201-1 4.13 RCWV x 2.5 or Max. overload voltage whichever is lower for 5 seconds |

| Insulation Resistance | >1000 MΩ | MIL-STD-202 Method 302 Apply 100VDC for 1 minute |

| Endurance | Power at 70°C, 1000hrs, Δ R± 0.20% | MIL-STD-202 Method 108 RCWV with 1.5 hrs ON and 0.5 hrs OFF 1000 hrs |

| Power at 70°C, 8000hrs, Δ R± 0.40% | ||

| Advanced temperature at 85°C, 1000hrs, Δ R± 0.30% | ||

| High Temperature Exposure | Δ R± 0.20%, +155°C | MIL-STD-202 Method 108 1000 hrs |

| Δ R± 0.30%, +175°C | ||

| Temperature Cycling | Δ R± 0.25% | JESD22 Method JA-104 -55℃ to +155℃, 1000 cycles |

| Biased Humidity | Power operation mode Δ R± 0.5% | MIL-STD-202 Method 103 1000hrs 85℃/85%RH 10% of operating power (≦100V) |

| Bending Strength (Board Flex) | Δ R± 0.1% | JIS-C-5201-1 4.33 Bending once for 60 seconds. Bending displacement 0603 0805 size: 3mm |

| Solderability | 95% min. coverage | JIS-C-5201-1 4.17 IEC-60115-1 4.17 245± 5°C for 3 seconds |

| Resistance to Soldering Heat | Δ R± 0.1% | JIS-C-5201-1 4.18 IEC-60115-1 4.18 260± 5°C for 10 seconds |

| Terminal strength | No broken | AEC-Q200-006 Force of 1.8kg for 60 seconds. |

| Mechanical Shock | Δ R± 0.1% | MIL-STD-202 Method 213 Wave Form: Tolerance for half sine shock pulse. Peak value is 100g's. Normal duration (D) is 6. |

| Vibration | Δ R± 0.1% | MIL-STD-202 Method 204 5 g's for 20 min., 12 cycles each of 3 orientations, 10-2000 Hz |

| ESD | Δ R± 0.5% | AEC-Q200-002 Human body model 0603 0.5KV; 0805 1.5KV |

| Resistance to solvents | Marking Unsmeared | MIL-STD-202 Method 215 Add Aqueous wash chemical - OKEM Clean or equivalent. Do not use banned solvents. |

| Flammability | No ignition of the tissue paper or scorching or the pinewood board | UL-94 V-0 or V-1 are acceptable. Electrical test not required. |

RCWV (Rated continuous working voltage)= √(P x R) or Max. Operating voltage whichever is lower.

☑ Storage Temperature: 15 ~ 28°C; Humidity < 80%RH

☑ Shelf Life: 2 years from production date.

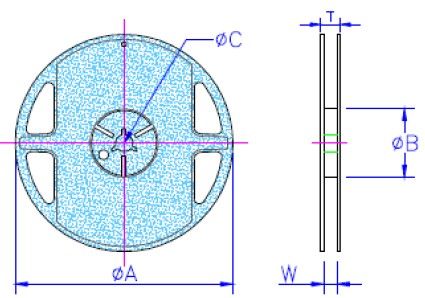

Packing Quantity & Reel Specifications (Unit :mm)

| Type | ØA | ØB | ØC | W | T | Paper Type(EA) | Emboss Plastic Tape(EA) |  |

|---|---|---|---|---|---|---|---|---|

| ARTP03 | 178.0±1.0 | 60.0+1.0 | 13.5±0.7 | 9.5±1.0 | 11.5±1.0 | 5,000 | - | |

| ARTP05 | 178.0±1.0 | 60.0+1.0 | 13.5±0.7 | 9.5±1.0 | 11.5±1.0 | 5,000 | - |

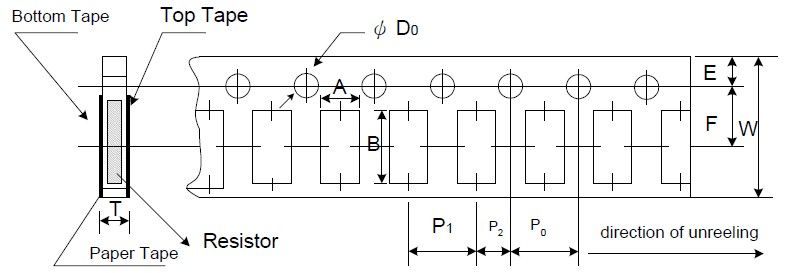

Paper Tape Specifications

| Type | A (mm) | B (mm) | W (mm) | E (mm) | F (mm) | P0 (mm) | P1 (mm) | P2 (mm) | ØD0 (mm) | T (mm) |

|---|---|---|---|---|---|---|---|---|---|---|

| ARTP03 | 1.10 ± 0.05 | 1.90 ± 0.05 | 8.00 ± 0.10 | 1.75 ± 0.05 | 3.50 ± 0.05 | 4.00 ± 0.10 | 4.00 ± 0.10 | 2.00 ± 0.05 | 1.55 ± 0.05 | 0.60 ± 0.03 |

| ARTP05 | 1.60 ± 0.05 | 2.37 ± 0.05 | 8.00 ± 0.10 | 1.75 ± 0.05 | 3.50 ± 0.05 | 4.00 ± 0.10 | 4.00 ± 0.10 | 2.00 ± 0.05 | 1.55 ± 0.05 | 0.75 ± 0.05 |

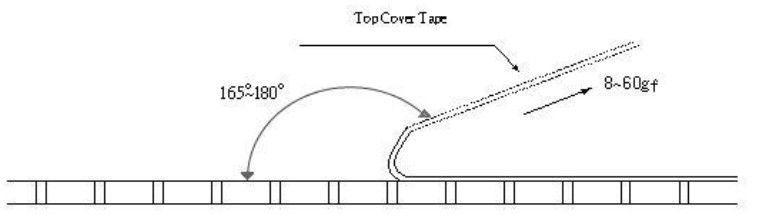

■ Peel force of top cover tape.

■ The peel speed shall be about 300mm/min ± 5%.

■ The peel force of top cover tape shall be between 8gf to 60gf.

Thin film Precision resistor 0.01%, TC2ppm, wirebondale, Anti-Crossive, MELF. Current sensing, Metal...

Read More

Ceramic high frequency chip inductors, small size to 01005. Thin film, multilayer, wirewound , ferrite...

Read More

Multilayer Ceramic capacitor offers high Voltage, high frequency, low noise, High Q, Low TCR. NPO, X7R,...

Read More