Applications automobiles

Résistance de précision à film mince 0,01%, TC2ppm, wirebondale, anti-corrosif, MELF. Détection de courant,...

Lire la suiteRésistance MELF de qualité automobile avec AEC-Q256 qualifiée pour répondre aux normes industrielles automobiles. Niveau avancé pour un environnement très critique.

CSRV Series0207 ±1% 50 1W Series2.67Ω 2K/Reel

| Taille | Tolérance | TCR (ppm /℃) | Puissance | Résistance (Ohm) | Emballage |

|---|---|---|---|---|---|

| 0207 | ±1% | 50 | 1W | 2.67 | 2K/Reel |

| Item Type |

Power Rating at 70°C | Operating Temp. Range | Max. Operating Voltage | Max. Overload Voltage | Resistance Range | TCR (PPM / °C) | ||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| ± 0.1% | ± 0.25% | ± 0.5% | ± 1% | ± 5% | ||||||||

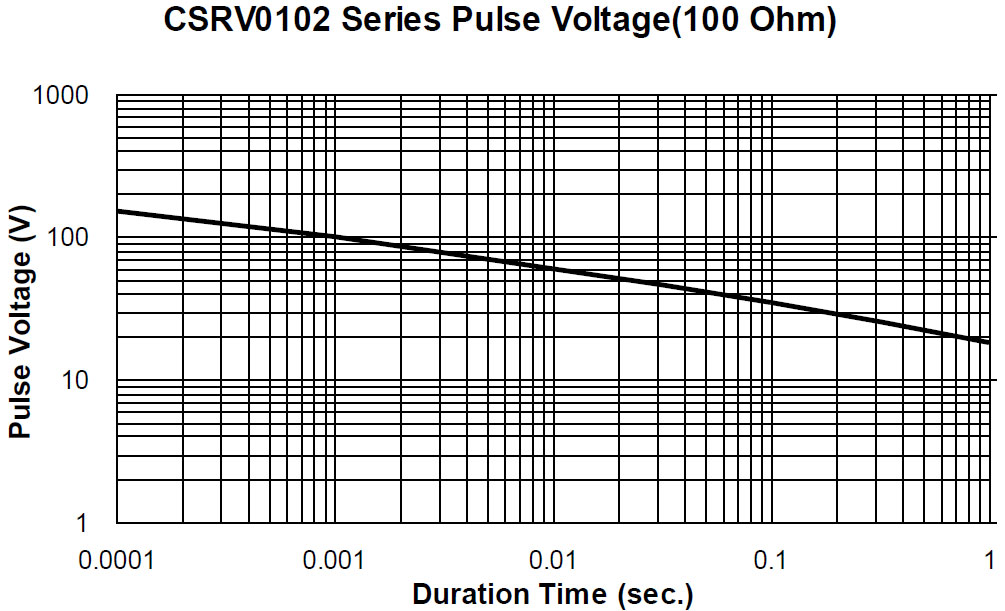

| 0102 | 1/5W | -55 ~ +155°C | 200V | 400V | 100Ω - 56KΩ | - | ± 15 | |||||

| 100Ω - 82KΩ | 49.9Ω - 200KΩ | 49.9Ω - 390KΩ | - | ± 25 | ||||||||

| 0.3W | - | 8.2Ω - 1MΩ | ± 50 | |||||||||

| - | 40Ω - 1MΩ | ± 100 | ||||||||||

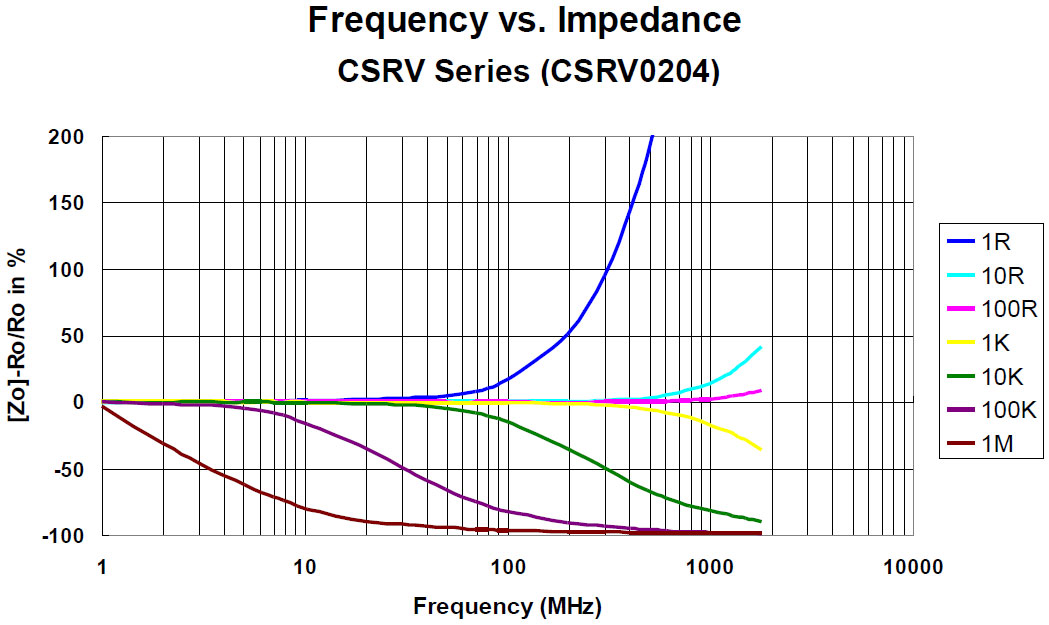

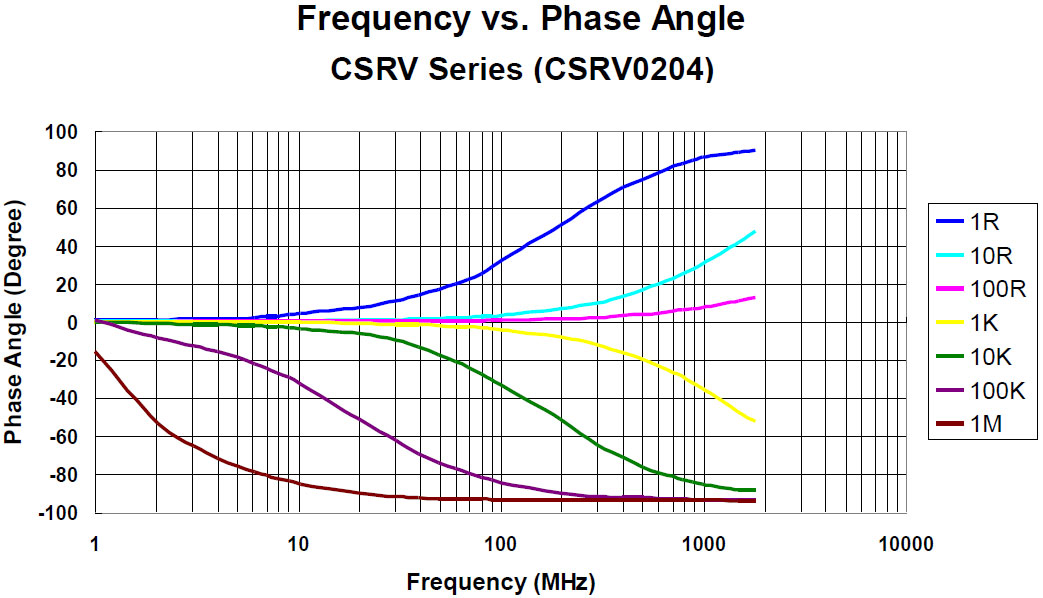

| 0204 | 2/5W | -55 ~ +155°C | 200V | 400V | 10Ω - 300KΩ | ± 15 | ||||||

| 10Ω - 1MΩ | 10Ω – 3.4MΩ | 4.02Ω - 3.4MΩ | ± 25 | |||||||||

| 10Ω - 1MΩ | 1Ω - 1MΩ | 1Ω – 3.4MΩ | 0.2Ω - 3.4MΩ | ± 50 | ||||||||

| - | 0.1Ω - 1MΩ | ± 100 | ||||||||||

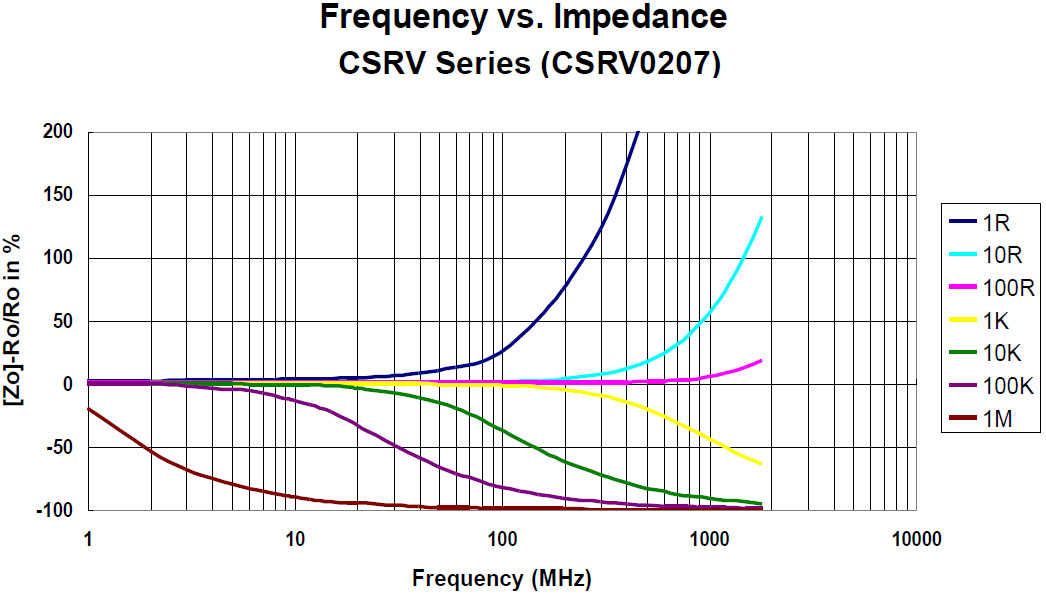

| 0207 | 1W | -55 ~ +155°C | 350V | 700V | 10Ω - 300KΩ | ± 15 | ||||||

| 10Ω - 1MΩ | 10Ω - 3.4MΩ | 4.02Ω - 3.4MΩ | ± 25 | |||||||||

| 10Ω - 1MΩ | 1Ω - 1MΩ | 1Ω - 3.4MΩ | 0.2Ω - 3.4MΩ | ± 50 | ||||||||

| - | 0.1Ω - 1MΩ | ± 100 | ||||||||||

Operating Voltage=√(P x R) or Max. Operating Voltage listed above, whichever is lower.

Overload Voltage=2.5*√(P x R) or Max. Overload Voltage listed above, whichever is lower.

RCWV (Rated Continuous Working Voltage)=√(P x R) or Max. Operating Voltage whichever is lower.

■ Viking is capable of manufacturing the optional spec based on customer's requirement.

| Item | Requirement | Test Method |

|---|---|---|

| Temperature Coefficient of Resistance (T.C.R.) | As Spec | JIS-C-5201-1 4.8 IEC-60115-1 4.8 At 25°C/-55°C and 25°C/ + 125°C, 25°C is the reference temperature |

| Short Time Overload | 10Ω-270KΩ: ± (0.1% + 0.01Ω) <10Ω & >270KΩ: ± (0.15% + 0.01Ω) 0102: ± (0.15% + 0.01Ω) |

JIS-C-5201-1 4.13 IEC-60115-1 4.13 RCWV x 2.5 or Max. Overload Voltage whichever is lower for 5 seconds |

| Insulation Resistance | ?10G | JIS-C-5201-1 4.6 IEC-60115-1 4.6 Max. Overload Voltage for 1 minute |

| Endurance | 10Ω-270KΩ: ± (0.25% + 0.01Ω) <10Ω & >270KΩ: ± (0.5% + 0.01Ω) 0102: ± (0.5% + 0.01Ω) |

JIS-C-5201-1 4.25 IEC-60115-1 4.25.1 MIL-STD-202 Method 108 70± 2°C, RCWV for 1000 hrs with 1.5 hrs "ON" and 0.5 hr "OFF" |

| Biased Humidity | 10Ω-270KΩ: ± (0.5% + 0.01Ω) <10Ω & >270KΩ: ± (1% + 0.01Ω) 0102: ± (2% + 0.01Ω) |

MIL-STD-202 Method 103 1000 hrs 85°C/85%RH 10% of operating power. |

| High Temperature Exposure | 10Ω-270KΩ: ± (0.25% + 0.01Ω) <10Ω & >270KΩ: ± (1% + 0.01Ω) 0102: ± (1% + 0.01Ω) |

MIL-STD-202 Method 108 at + 155°C for 1000 hrs |

| Board Flex | 10Ω-270KΩ: ± (0.1% + 0.01Ω) <10Ω & >270KΩ: ± (0.5% + 0.01Ω) 0102: ± (0.5% + 0.01Ω) |

AEC-Q200-005 Bending once for 60 seconds with 2mm |

| Solderability | 95% min. coverage | JIS-C-5201-1 4.17 IEC-60115-1 4.17 J-STD-002 245± 5°C for 3 seconds |

| Resistance to Soldering Heat | 10Ω-270KΩ: ± (0.1% + 0.01Ω) <10Ω & >270KΩ: ± (0.25% + 0.01Ω) 0102: ± (0.25% + 0.01Ω) |

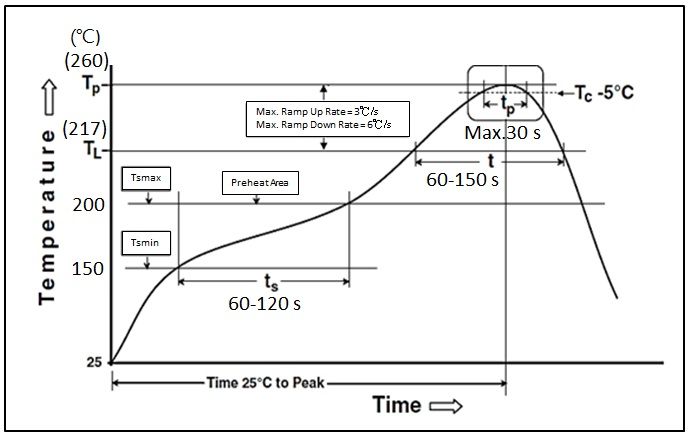

MIL-STD-202 Method 210 260± 5°C for 10 seconds |

| Voltage Proof | No breakdown or flashover | JIS-C-5201-1 4.7 IEC-60115-1 4.7 1.42 times Max. Operating Voltage for 1 minute |

| Leaching | Individual leaching area ≦ 5% Total leaching area ≦ 10% |

JIS-C-5201-1 4.18 IEC-60068-2-58 8.2.1 260± 5°C for 30 seconds |

| Temperature Cycling | 10Ω-270KΩ: ± (0.25% + 0.01Ω) <10Ω & >270KΩ: ± (0.5% + 0.01Ω) 0102: ± (1% + 0.01Ω) |

JESD22 Method JA-104 -55°C to + 125°C, 1000 cycles |

| Mechanical Shock | ± (0.25% + 0.01Ω) | MIL-STD-202 Method 213 Wave Form: Tolerance for half sine shock pulse. Peak value is 100g's. Normal duration (D) is 6. |

| Vibration | ± (0.5% + 0.01Ω) | MIL-STD-202 Method 204 5 g's for 20 min., 12 cycles each of 3 orientations, 10-2000 Hz |

| ESD | ± (0.5% + 0.01Ω) | AEC-Q200-002 Human body, 2KV |

| Resistance to Solvents | No visible damage on appearance and marking. | MIL-STD-202 Method 215 Add Aqueous wash chemical - OKEM Clean or equivalent. Do not use banned solvents. |

| Terminal Strength | No broken | AEC-Q200-006 Force of 1.8kg for 60 seconds. |

| Flammability | No ignition of the tissue paper or scorching or the pinewood board | UL-94 V-0 or V-1 are acceptable. Electrical test not required. |

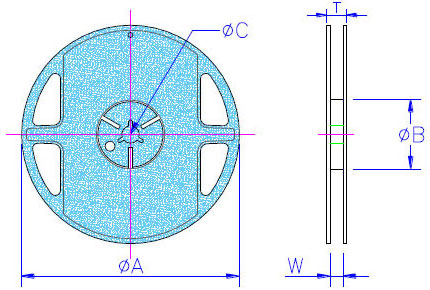

Packaging Quantity & Reel Specifications

| Type | Reel Diameter | Φ A (mm) | Φ B (mm) | Φ C (mm) | W (mm) | T (mm) | Emboss Plastic Tape (EA) |

|---|---|---|---|---|---|---|---|

| CSRV0102 | 7 inch | 178.5 ± 1.5 | 60.0+1.0 | 13.0 ± 0.2 | 9.0 ± 0.5 | 12.5 ± 0.5 | 3,000 |

| CSRV0204 | 7 inch | 178.5 ± 1.5 | 60.0+1.0 | 13.0 ± 0.2 | 9.0 ± 0.5 | 12.5 ± 0.5 | 3,000 |

| CSRV0207 | 7 inch | 178.5 ± 1.5 | 60.0+1.0 | 13.0 ± 0.5 | 13.0 ± 0.5 | 15.5 ± 0.5 | 2,000 |

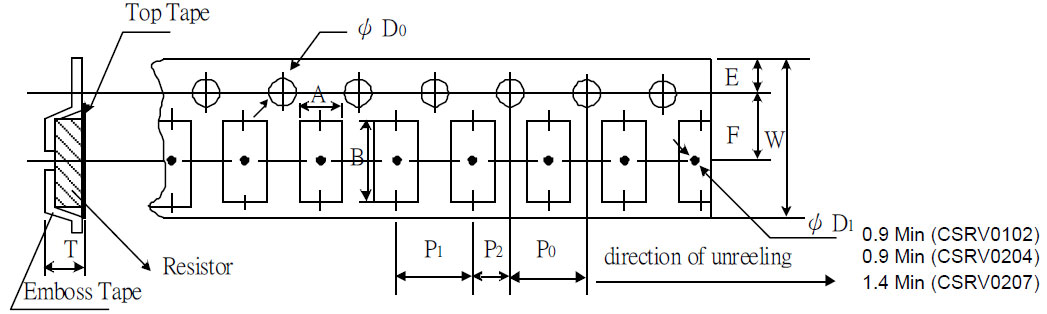

Emboss Plastic Tape Specifications

| Type | A (mm) | B (mm) | W (mm) | E (mm) | F (mm) | P0 (mm) | P1 (mm) | P2 (mm) | Φ D0 (mm) | T (mm) |

|---|---|---|---|---|---|---|---|---|---|---|

| CSRV0102 | 1.30 ± 0.10 | 2.40 ± 0.10 | 8.0 ± 0.10 | 1.75 ± 0.10 | 3.50 ± 0.05 | 4.00 ± 0.10 | 4.00 ± 0.10 | 2.00 ± 0.05 | 1.50 + 0.10 | 1.50 ± 0.10 |

| CSRV0204 | 1.55 ± 0.10 | 3.65 ± 0.10 | 8.0 ± 0.10 | 1.75 ± 0.10 | 3.50 ± 0.05 | 4.00 ± 0.10 | 4.00 ± 0.10 | 2.00 ± 0.05 | 1.50 + 0.10 | 1.80 ± 0.10 |

| CSRV0207 | 2.40 ± 0.10 | 6.15 ± 0.10 | 12.0 ± 0.10 | 1.75 ± 0.10 | 5.50 ± 0.05 | 4.00 ± 0.10 | 4.00 ± 0.10 | 2.00 ± 0.05 | 1.50 + 0.10 | 2.70 ± 0.10 |

| ±5% | E-24 | 1.0 | 1.1 | 1.2 | 1.3 | 1.5 | 1.6 | 1.8 | 2.0 | 2.2 | 2.4 | 2.7 | 3.0 | 3.3 | 3.6 | 3.9 | 4.3 | 4.7 | 5.1 | 5.6 | 6.2 | 6.8 | 7.5 | 8.2 | 9.1 |

| ±1% | E-96 | 1.00 | 1.02 | 1.05 | 1.07 | 1.10 | 1.13 | 1.15 | 1.18 | 1.21 | 1.24 | 1.27 | 1.30 | 1.33 | 1.37 | 1.40 | 1.43 | 1.47 | 1.50 | 1.54 | 1.58 | 1.62 | 1.65 | 1.69 | 1.74 |

| 1.78 | 1.82 | 1.87 | 1.91 | 1.96 | 2.00 | 2.05 | 2.10 | 2.15 | 2.21 | 2.26 | 2.32 | 2.37 | 2.43 | 2.49 | 2.55 | 2.61 | 2.67 | 2.74 | 2.80 | 2.87 | 2.94 | 3.01 | 3.09 | ||

| 3.16 | 3.24 | 3.32 | 3.40 | 3.48 | 3.57 | 3.65 | 3.74 | 3.83 | 3.92 | 4.02 | 4.12 | 4.22 | 4.32 | 4.42 | 4.53 | 4.64 | 4.75 | 4.87 | 4.99 | 5.11 | 5.23 | 5.36 | 5.49 | ||

| 5.62 | 5.76 | 5.90 | 6.04 | 6.19 | 6.34 | 6.49 | 6.65 | 6.81 | 6.98 | 7.15 | 7.32 | 7.50 | 7.68 | 7.87 | 8.06 | 8.25 | 8.45 | 8.66 | 8.87 | 9.09 | 9.31 | 9.53 | 9.76 | ||

| ±0.5% ±0.25% ±0.1% |

E-192 | 10.0 | 10.1 | 10.2 | 10.4 | 10.5 | 10.6 | 10.7 | 10.9 | 11.0 | 11.1 | 11.3 | 11.4 | 11.5 | 11.7 | 11.8 | 12.0 | 12.1 | 12.3 | 12.4 | 12.6 | 12.7 | 12.9 | 13.0 | 13.2 |

| 13.3 | 13.5 | 13.7 | 13.8 | 14.0 | 14.2 | 14.3 | 14.5 | 14.7 | 14.9 | 15.0 | 15.2 | 15.4 | 15.6 | 15.8 | 16.0 | 16.2 | 16.4 | 16.5 | 16.7 | 16.9 | 17.2 | 17.4 | 17.6 | ||

| 17.8 | 18.0 | 18.2 | 18.4 | 18.7 | 18.9 | 19.1 | 19.3 | 19.6 | 19.8 | 20.0 | 20.3 | 20.5 | 20.8 | 21.0 | 21.3 | 21.5 | 21.8 | 22.1 | 22.3 | 22.6 | 22.9 | 23.2 | 23.4 | ||

| 23.7 | 24.0 | 24.3 | 24.6 | 24.9 | 25.2 | 25.5 | 25.8 | 26.1 | 26.4 | 26.7 | 27.1 | 27.4 | 27.7 | 28.0 | 28.4 | 28.7 | 29.1 | 29.4 | 29.8 | 30.1 | 30.5 | 30.9 | 31.2 | ||

| 31.6 | 32.0 | 32.4 | 32.8 | 33.2 | 33.6 | 34.0 | 34.4 | 34.8 | 35.2 | 35.7 | 36.1 | 36.5 | 37.0 | 37.4 | 37.9 | 38.3 | 38.8 | 39.2 | 39.7 | 40.2 | 40.7 | 41.2 | 41.7 | ||

| 42.2 | 42.7 | 43.2 | 43.7 | 44.2 | 44.8 | 45.3 | 45.9 | 46.4 | 47.0 | 47.5 | 48.1 | 48.7 | 49.3 | 49.9 | 50.5 | 51.1 | 51.7 | 52.3 | 53.0 | 53.6 | 54.2 | 54.9 | 55.6 | ||

| 56.2 | 56.9 | 57.6 | 58.3 | 59.0 | 59.7 | 60.4 | 61.2 | 61.9 | 62.6 | 63.4 | 64.2 | 64.9 | 65.7 | 66.5 | 67.3 | 68.1 | 69.0 | 69.8 | 70.6 | 71.5 | 72.3 | 73.2 | 74.1 | ||

| 75.0 | 75.9 | 76.8 | 77.7 | 78.7 | 79.6 | 80.6 | 81.6 | 82.5 | 83.5 | 84.5 | 85.6 | 86.6 | 87.6 | 88.7 | 89.8 | 90.9 | 92.0 | 93.1 | 94.2 | 95.3 | 96.5 | 97.6 | 98.8 |

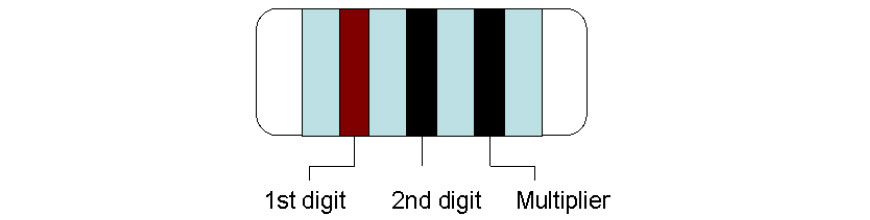

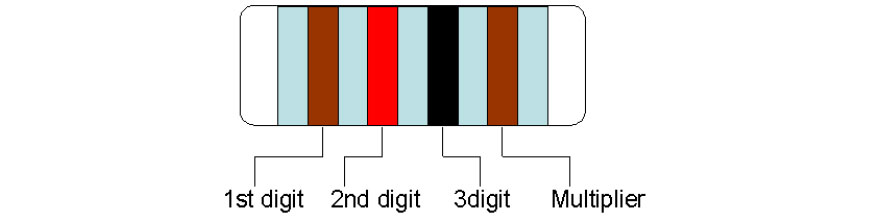

| Color | Digit | Multiplier |

|---|---|---|

| Silver | - | 10-2 |

| Gold | - | 10-1 |

| Black | 0 | 100 |

| Brown | 1 | 101 |

| Red | 2 | 102 |

| Orange | 3 | 103 |

| Yellow | 4 | 104 |

| Green | 5 | 105 |

| Blue | 6 | 106 |

| Violet | 7 | 107 |

| Grey | 8 | 108 |

| White | 9 | 109 |

※Resistance more than two significant figures (<1R) or more than three significant figures (>1R) will not provide color code.

Résistance de précision à film mince 0,01%, TC2ppm, wirebondale, anti-corrosif, MELF. Détection de courant,...

Lire la suite

Inducteurs à puce céramiques haute fréquence, petite taille jusqu'à 01005. Inducteur à film mince,...

Lire la suite

Le condensateur céramique multicouche offre une haute tension, une haute fréquence, un faible bruit,...

Lire la suite