APLICACIONES AUTOMOTRICES

Resistor de precisión de película delgada 0.01%, TC2ppm, wirebondale, anti-corrosivo, MELF. Detección...

Lee masInductor de ferrita de chip enrollado en alambre, de alta corriente, tipo moldeado y abierto están disponibles. Tamaño pequeño hasta 0603, muy buena soldabilidad por soldadura por flujo o soldador, soldadura por ola. Altamente resistente a choques mecánicos y presión. Muy confiable en entornos de cambios repentinos de temperatura y humedad. Características super Q.

NL Series0805 ±10% 5.6μH 0.65 Ω 480mA 12 47

| Tamaño | Tolerancia | Inductancia | Condición de prueba | DCR (Ω) máx. | IDC (mA) | Q | SRF |

|---|---|---|---|---|---|---|---|

| 0805 | ±10% | 5.6 | 7.9MHz | 0.65 | 480 | 12 | 47 |

NL03 Wound Chip Inductors (Ferrite / Open Type) / Large Current Type

| Codes | Inductance (uH) | Tolerance | Q min. | Test Freq. (MHz) | SRF (MHz) min. | DCR (Ω) max. | IDC (mA) max. | Color Code |

|---|---|---|---|---|---|---|---|---|

| R10 | 0.10 | ± 5, ± 10, ± 20% | 12 | 7.9 | 1150 | 0.13 | 1700 | Black |

| R12 | 0.12 | ± 5, ± 10, ± 20% | 12 | 7.9 | 1100 | 0.15 | 1700 | Orange |

| R15 | 0.15 | ± 5, ± 10, ± 20% | 15 | 7.9 | 1050 | 0.15 | 1600 | Brown |

| R18 | 0.18 | ± 5, ± 10, ± 20% | 15 | 7.9 | 950 | 0.15 | 1500 | Green |

| R22 | 0.22 | ± 5, ± 10, ± 20% | 15 | 7.9 | 900 | 0.30 | 1200 | Red |

| R24 | 0.24 | ± 5, ± 10, ± 20% | 15 | 7.9 | 850 | 0.16 | 1460 | Green |

| R27 | 0.27 | ± 5, ± 10, ± 20% | 15 | 7.9 | 835 | 0.30 | 1460 | Yellow |

| R33 | 0.33 | ± 5, ± 10, ± 20% | 15 | 7.9 | 725 | 0.40 | 1420 | Orange |

| R39 | 0.39 | ± 5, ± 10, ± 20% | 15 | 7.9 | 680 | 0.41 | 1400 | Blue |

| R47 | 0.47 | ± 5, ± 10, ± 20% | 15 | 7.9 | 640 | 0.43 | 1400 | Black |

| R56 | 0.56 | ± 5, ± 10, ± 20% | 15 | 7.9 | 630 | 0.44 | 1400 | Brown |

| R68 | 0.68 | ± 5, ± 10, ± 20% | 15 | 7.9 | 510 | 0.52 | 1340 | Red |

| R78 | 0.78 | ± 5, ± 10, ± 20% | 15 | 7.9 | 465 | 0.63 | 1300 | Orange |

| R82 | 0.82 | ± 5, ± 10, ± 20% | 15 | 7.9 | 460 | 0.69 | 1200 | Yellow |

| 1R0 | 1.0 | ± 5, ± 10, ± 20% | 15 | 7.9 | 320 | 0.81 | 1100 | Green |

| 1R2 | 1.2 | ± 5, ± 10, ± 20% | 15 | 7.9 | 270 | 0.87 | 1100 | Blue |

| 1R5 | 1.5 | ± 5, ± 10, ± 20% | 15 | 7.9 | 230 | 0.96 | 920 | Violet |

| 1R8 | 1.8 | ± 5, ± 10, ± 20% | 15 | 7.9 | 210 | 1.10 | 900 | Gray |

| 2R2 | 2.2 | ± 5, ± 10, ± 20% | 15 | 7.9 | 115 | 1.20 | 740 | White |

| 2R7 | 2.7 | ± 5, ± 10, ± 20% | 15 | 7.9 | 100 | 1.38 | 700 | Black |

| 3R3 | 3.3 | ± 5, ± 10, ± 20% | 15 | 7.9 | 84 | 1.50 | 680 | Brown |

| 3R9 | 3.9 | ± 5, ± 10, ± 20% | 15 | 7.9 | 75 | 1.50 | 600 | Red |

| 4R7 | 4.7 | ± 5, ± 10, ± 20% | 15 | 7.9 | 67 | 2.10 | 580 | Orange |

| 5R6 | 5.6 | ± 5, ± 10, ± 20% | 15 | 7.9 | 55 | 2.37 | 540 | Yellow |

| 6R8 | 6.8 | ± 5, ± 10, ± 20% | 15 | 7.9 | 48 | 3.10 | 500 | Green |

| 7R8 | 7.8 | ± 5, ± 10, ± 20% | 15 | 7.9 | 40 | 3.35 | 460 | Blue |

| 8R2 | 8.2 | ± 5, ± 10, ± 20% | 15 | 7.9 | 38 | 3.50 | 440 | Violet |

| 100 | 10 | ± 5, ± 10, ± 20% | 15 | 7.9 | 32 | 4.46 | 400 | Gray |

NL05 Wire Wound Chip Inductors (Ferrite / Open Type) / Large Current Type

| Codes | Inductance (uH) | Tolerance | Q typ. | Test Freq. (MHz) | SRF (MHz) typ. | DCR (Ω) max. | IDC (mA) typ. | Color Code |

|---|---|---|---|---|---|---|---|---|

| R47 | 0.47 | ± 5, ± 10, ± 20% | 14 | 7.9 | 850 | 0.156 | 1400 | Blue |

| R68 | 0.68 | ± 5, ± 10, ± 20% | 14 | 7.9 | 765 | 0.195 | 1200 | Gray |

| 1R0 | 1.00 | ± 5, ± 10, ± 20% | 14 | 7.9 | 208 | 0.169 | 1100 | Black |

| 1R2 | 1.20 | ± 5, ± 10, ± 20% | 14 | 7.9 | 159 | 0.208 | 960 | Red |

| 1R5 | 1.50 | ± 5, ± 10, ± 20% | 14 | 7.9 | 159 | 0.221 | 920 | Brown |

| 1R8 | 1.80 | ± 5, ± 10, ± 20% | 14 | 7.9 | 112 | 0.260 | 860 | Orange |

| 2R2 | 2.20 | ± 5, ± 10, ± 20% | 13 | 7.9 | 87 | 0.286 | 740 | Red |

| 2R7 | 2.70 | ± 5, ± 10, ± 20% | 13 | 7.9 | 72 | 0.325 | 680 | Yellow |

| 3R3 | 3.30 | ± 5, ± 10, ± 20% | 12 | 7.9 | 70 | 0.364 | 620 | Orange |

| 3R9 | 3.90 | ± 5, ± 10, ± 20% | 14 | 7.9 | 61 | 0.494 | 580 | Green |

| 4R7 | 4.70 | ± 5, ± 10, ± 20% | 14 | 7.9 | 51 | 0.559 | 520 | Yellow |

| 5R6 | 5.60 | ± 5, ± 10, ± 20% | 12 | 7.9 | 47 | 0.650 | 480 | Blue |

| 6R8 | 6.80 | ± 5, ± 10, ± 20% | 14 | 7.9 | 46 | 0.884 | 420 | Green |

| 8R2 | 8.20 | ± 5, ± 10, ± 20% | 13 | 7.9 | 33 | 0.949 | 400 | Violet |

| 100 | 10 | ± 5, ± 10, ± 20% | 14 | 2.5 | 31 | 1.105 | 360 | Blue |

| 120 | 12 | ± 5, ± 10, ± 20% | 14 | 2.5 | 30 | 1.17 | 340 | Gray |

| 150 | 15 | ± 5, ± 10, ± 20% | 15 | 2.5 | 28 | 1.82 | 300 | Violet |

| 180 | 18 | ± 5, ± 10, ± 20% | 15 | 2.5 | 27 | 2.01 | 280 | White |

| 220 | 22 | ± 5, ± 10, ± 20% | 15 | 2.5 | 20 | 2.288 | 240 | Gray |

| 270 | 27 | ± 5, ± 10, ± 20% | 15 | 2.5 | 17 | 2.60 | 220 | Black |

| 330 | 33 | ± 5, ± 10, ± 20% | 15 | 2.5 | 17 | 3.055 | 200 | White |

| 470 | 47 | ± 5, ± 10, ± 20% | 14 | 2.5 | 15 | 4.42 | 160 | Black |

| 560 | 56 | ± 5, ± 10, ± 20% | 14 | 2.5 | 10 | 5.746 | 150 | Yellow |

| 680 | 68 | ± 5, ± 10, ± 20% | 14 | 2.5 | 10 | 5.785 | 140 | Brown |

| 820 | 82 | ± 5, ± 10, ± 20% | 14 | 2.5 | 10 | 9.75 | 100 | Orange |

| 101 | 100 | ± 5, ± 10, ± 20% | 10 | 1 | 9 | 9.75 | 100 | Red |

NL10 Wire Wound Chip Inductors (Ferrite / Molding Type) / Large Current Type

| Codes | Inductance (uH) | Tolerance | Q min. | Test Freq. (MHz) | SRF (MHz) typ. | DCR (Ω) max. | IDC (mA) max. |

|---|---|---|---|---|---|---|---|

| 1R0 | 1.0 | ± 5%,± 20% | 10 | 7.96 | 145 | 0.156 | 770 |

| 1R5 | 1.5 | ± 5%,± 20% | 10 | 7.96 | 100 | 0.195 | 580 |

| 2R2 | 2.2 | ± 5%,± 20% | 10 | 7.96 | 80 | 0.260 | 480 |

| 3R3 | 3.3 | ± 5%,± 20% | 10 | 7.96 | 60 | 0.325 | 400 |

| 4R7 | 4.7 | ± 5%,± 20% | 10 | 7.96 | 50 | 0.520 | 320 |

| 6R8 | 6.8 | ± 5%,± 20% | 10 | 7.96 | 40 | 0.650 | 280 |

| 100 | 10 | ± 5%,± 10% | 15 | 2.52 | 30 | 1.105 | 220 |

| 150 | 15 | ± 5%,± 10% | 15 | 2.52 | 27 | 1.690 | 180 |

| 220 | 22 | ± 5%,± 10% | 15 | 2.52 | 22 | 2.600 | 145 |

| 270 | 27 | ± 5%,± 10% | 15 | 2.52 | 19 | 3.000 | 125 |

| 330 | 33 | ± 5%,± 10% | 15 | 2.52 | 17 | 3.640 | 115 |

| 470 | 47 | ± 5%,± 10% | 20 | 2.52 | 15 | 5.460 | 105 |

| 680 | 68 | ± 5%,± 10% | 20 | 2.52 | 11 | 8.450 | 85 |

| 820 | 82 | ± 5%,± 10% | 20 | 2.52 | 10 | 8.710 | 80 |

| 101 | 100 | ± 5%,± 10% | 20 | 0.796 | 9 | 10.140 | 75 |

NL12 Wire Wound Chip Inductors (Ferrite / Molding Type) / Large Current Type

| Codes | Inductance (uH) | Tolerance | Q min. | Test Freq. (MHz) | SRF (MHz) typ. | DCR (Ω) max. | IDC (mA) max. |

|---|---|---|---|---|---|---|---|

| 1R0 | 1.0 | ± 5%,± 10% | 10 | 7.96 | 265 | 0.11 | 1050 |

| 1R2 | 1.2 | ± 5%,± 10% | 10 | 7.96 | 180 | 0.12 | 1000 |

| 1R5 | 1.5 | ± 5%,± 10% | 10 | 7.96 | 170 | 0.15 | 950 |

| 1R8 | 1.8 | ± 5%,± 10% | 10 | 7.96 | 105 | 0.16 | 900 |

| 2R2 | 2.2 | ± 5%,± 10% | 10 | 7.96 | 80 | 0.18 | 850 |

| 2R7 | 2.7 | ± 5%,± 10% | 10 | 7.96 | 60 | 0.20 | 800 |

| 3R3 | 3.3 | ± 5%,± 10% | 10 | 7.96 | 55 | 0.22 | 750 |

| 3R9 | 3.9 | ± 5%,± 10% | 10 | 7.96 | 45 | 0.24 | 700 |

| 4R7 | 4.7 | ± 5%,± 10% | 10 | 7.96 | 43 | 0.27 | 650 |

| 5R6 | 5.6 | ± 5%,± 10% | 10 | 7.96 | 40 | 0.30 | 650 |

| 6R8 | 6.8 | ± 5%,± 10% | 10 | 7.96 | 35 | 0.35 | 600 |

| 8R2 | 8.2 | ± 5%,± 10% | 10 | 7.96 | 30 | 0.40 | 600 |

| 100 | 10 | ± 5%,± 10% | 10 | 2.52 | 27 | 0.50 | 550 |

| 120 | 12 | ± 5%,± 10% | 10 | 2.52 | 25 | 0.60 | 500 |

| 150 | 15 | ± 5%,± 10% | 10 | 2.52 | 20 | 0.70 | 450 |

| 180 | 18 | ± 5%,± 10% | 10 | 2.52 | 19 | 0.80 | 400 |

| 220 | 22 | ± 5%,± 10% | 10 | 2.52 | 18 | 0.90 | 370 |

| 270 | 27 | ± 5%,± 10% | 10 | 2.52 | 16 | 1.20 | 330 |

| 330 | 33 | ± 5%,± 10% | 10 | 2.52 | 15 | 1.40 | 300 |

| 390 | 39 | ± 5%,± 10% | 10 | 2.52 | 13 | 1.60 | 280 |

| 470 | 47 | ± 5%,± 10% | 10 | 2.52 | 12 | 1.90 | 260 |

| 560 | 56 | ± 5%,± 10% | 10 | 2.52 | 10 | 2.20 | 240 |

| 680 | 68 | ± 5%,± 10% | 10 | 2.52 | 9.5 | 2.60 | 220 |

| 820 | 82 | ± 5%,± 10% | 10 | 2.52 | 8.5 | 3.50 | 200 |

| 101 | 100 | ± 5%,± 10% | 20 | 0.796 | 8.0 | 4.00 | 180 |

| 121 | 120 | ± 5%,± 10% | 20 | 0.796 | 7.0 | 4.50 | 160 |

| 151 | 150 | ± 5%,± 10% | 20 | 0.796 | 6.5 | 6.50 | 140 |

| 181 | 180 | ± 5%,± 10% | 20 | 0.796 | 6.0 | 7.50 | 120 |

| 221 | 220 | ± 5%,± 10% | 20 | 0.796 | 5.5 | 9.00 | 120 |

| 271 | 270 | ± 5%,± 10% | 20 | 0.796 | 5.0 | 11.0 | 100 |

| 331 | 330 | ± 5%,± 10% | 20 | 0.796 | 4.5 | 13.0 | 90 |

| 391 | 390 | ± 5%,± 10% | 20 | 0.796 | 4.0 | 14.0 | 85 |

| 471 | 470 | ± 5%,± 10% | 20 | 0.796 | 3.5 | 16.0 | 75 |

| 561 | 560 | ± 5%,± 10% | 20 | 0.796 | 3.0 | 21.0 | 70 |

| 681 | 680 | ± 5%,± 10% | 20 | 0.796 | 2.5 | 24.0 | 65 |

NL20 Wire Wound Chip Inductors (Ferrite / Molding Type) / Large Current Type

| Codes | Inductance (uH) | Tolerance | Q min. | Test Freq. (MHz) | SRF (MHz) min. | DCR (Ω) max. | IDC (mA) max. |

|---|---|---|---|---|---|---|---|

| 1R0 | 1.0 | ± 10,± 20% | 10 | 7.96 | 95 | 0.03 | 1800 |

| 1R2 | 1.2 | ± 10, ± 20% | 10 | 7.96 | 70 | 0.035 | 1700 |

| 1R5 | 1.5 | ± 10, ± 20% | 10 | 7.96 | 55 | 0.04 | 1600 |

| 1R8 | 1.8 | ± 10, ± 20% | 10 | 7.96 | 47 | 0.05 | 1400 |

| 2R2 | 2.2 | ± 10, ± 20% | 10 | 7.96 | 42 | 0.06 | 1300 |

| 2R7 | 2.7 | ± 10, ± 20% | 10 | 7.96 | 37 | 0.07 | 1200 |

| 3R3 | 3.3 | ± 10, ± 20% | 10 | 7.96 | 34 | 0.08 | 1120 |

| 3R9 | 3.9 | ± 10, ± 20% | 10 | 7.96 | 32 | 0.09 | 1050 |

| 4R7 | 4.7 | ± 10, ± 20% | 10 | 7.96 | 29 | 0.11 | 950 |

| 5R6 | 5.6 | ± 10, ± 20% | 10 | 7.96 | 26 | 0.13 | 880 |

| 6R8 | 6.8 | ± 10, ± 20% | 10 | 7.96 | 24 | 0.15 | 810 |

| 8R2 | 8.2 | ± 10, ± 20% | 10 | 7.96 | 22 | 0.18 | 750 |

| 100 | 10 | ± 10, ± 20% | 10 | 2.52 | 19 | 0.21 | 690 |

| 120 | 12 | ± 10, ± 20% | 10 | 2.52 | 17 | 0.25 | 630 |

| 150 | 15 | ± 10, ± 20% | 10 | 2.52 | 16 | 0.30 | 580 |

| 180 | 18 | ± 10, ± 20% | 10 | 2.52 | 14 | 0.36 | 530 |

| 220 | 22 | ± 5, ± 10% | 10 | 2.52 | 13 | 0.43 | 480 |

| 270 | 27 | ± 5, ± 10% | 10 | 2.52 | 11.5 | 0.52 | 440 |

| 330 | 33 | ± 5, ± 10% | 10 | 2.52 | 10.5 | 0.62 | 400 |

| 390 | 39 | ± 5, ± 10% | 10 | 2.52 | 9.5 | 0.72 | 370 |

| 470 | 47 | ± 5, ± 10% | 10 | 2.52 | 8.5 | 0.85 | 340 |

| 560 | 56 | ± 5, ± 10% | 10 | 2.52 | 7.8 | 1.00 | 310 |

| 680 | 68 | ± 5, ± 10% | 10 | 2.52 | 7.0 | 1.2 | 290 |

| 820 | 82 | ± 5, ± 10% | 10 | 2.52 | 6.4 | 1.4 | 270 |

| 101 | 100 | ± 5, ± 10% | 20 | 0.796 | 6.0 | 1.6 | 250 |

| 121 | 120 | ± 5, ± 10% | 20 | 0.796 | 5.4 | 1.9 | 230 |

| 151 | 150 | ± 5, ± 10% | 20 | 0.796 | 4.8 | 2.2 | 210 |

| 181 | 180 | ± 5, ± 10% | 20 | 0.796 | 4.4 | 2.8 | 190 |

| 221 | 220 | ± 5, ± 10% | 20 | 0.796 | 3.9 | 3.4 | 170 |

| 271 | 270 | ± 5, ± 10% | 20 | 0.796 | 3.6 | 4.2 | 155 |

| 331 | 330 | ± 5, ± 10% | 20 | 0.796 | 3.2 | 4.9 | 140 |

| 391 | 390 | ± 5, ± 10% | 20 | 0.796 | 2.9 | 5.8 | 130 |

| 471 | 470 | ± 5, ± 10% | 20 | 0.796 | 2.6 | 7.0 | 120 |

| 561 | 560 | ± 5, ± 10% | 20 | 0.796 | 2.4 | 8.5 | 110 |

| 681 | 680 | ± 5, ± 10% | 20 | 0.796 | 2.2 | 10 | 100 |

| 821 | 820 | ± 5, ± 10% | 20 | 0.796 | 2.0 | 13 | 90 |

| 102 | 1000 | ± 5, ± 10% | 20 | 0.252 | 1.8 | 15 | 85 |

Electrical Performance Test

| Item | Requirement | Test Method |

|---|---|---|

| Inductance | Refer to standard electrical characteristic spec. | HP4291 or HP4284 |

| Q | HP4291 or HP4284 | |

| SRF | HP4291 | |

| DC Resistance DCR | Agilent 34401A | |

| Rated Current IDC | Applied the current to coils, The inductance change should be less than 10% to initial value. |

Mechanical Performance Test

| Item | Requirement | Test Method |

|---|---|---|

| Solderability | The electrodes shall be at least 90% covered with new solder coating | Lead-free inductor: after fluxing (alpha 100 or equiv), inductor shall be dipped in a melted solder bath at 245 ± 5°C, 5 ± 0.5 seconds |

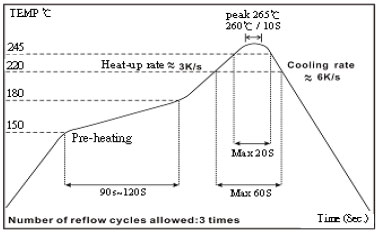

| Resistance to Soldering Heat | Appearance: No damage | Pre-heating: 150°C, 1min. Solder Temperature: 260 ± 5°C Immersion Time: 10 ± 1 seconds |

| Vibration | Appearance: No damage L change: within ± 10% Q change: within ± 30% DCR: within specification |

Test device shall be soldered on the substrate Oscillation Frequency: 10 to 55 to 10Hz for 1 min. Amplitude: 1.5 mm Time: 2 hrs for each axis (X, Y & Z), total 6 hrs |

Climatic Test

| Item | Requirement | Test Method | |||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Temperature Cycle | Appearance: No damage L change: within ± 10% Q change: within ± 30% DCR: within specification |

One cycle:

Total: 100 cycles |

|||||||||||||||

| Damp Heat with Load | Temperature: 40 ± 2°C Relative Humidity: 90 ~ 95% Time: 1000 hrs Measured after exposure in the room condition for 24 hrs |

||||||||||||||||

| High Temperature Storage | Temperature: 85 ± 3°C Applied Current: Rated Current Time: 1000 hrs Measured after exposure in the room condition for 24 hrs |

||||||||||||||||

| Low Temperature Storage | Temperature: -25 ± 3°C Time: 1000 hrs Measured after exposure in the room condition for 24 hrs |

☑ Storage Temperature: 15 ~ 28°C; Humidity < 80%RH

☑ Operating Temperature Range: -40 ~ +85°C

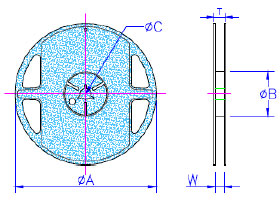

Packaging Quantity & Reel Specifications (Unit : mm)

| Type | Ø A | Ø B | Ø C | W | T | Quantity (EA) |  |

|---|---|---|---|---|---|---|---|

| NL03 | 178 ± 2.0 | 60 ± 0.5 | 13 ± 0.3 | 9 ± 0.3 | 12 ± 1.0 | 4000 | |

| NL05 | 178 ± 2.0 | 60 ± 0.5 | 13 ± 0.3 | 9 ± 0.3 | 12 ± 1.0 | 2000 | |

| NL08 | 178 ± 2.0 | 60 ± 0.5 | 13 ± 0.3 | 9 ± 0.3 | 12 ± 1.0 | 2000 | |

| NL10 | 178 ± 2.0 | 60 ± 0.5 | 13 ± 0.3 | 9 ± 0.3 | 12 ± 1.0 | 2000 | |

| NL12 | 178 ± 2.0 | 80 ± 0.5 | 13 ± 0.3 | 13.2 ± 0.3 | 16 ± 1.0 | 500 | |

| NL20 | 330 ± 2.0 | 100 ± 0.5 | 13 ± 0.3 | 17.4 ± 0.3 | 22 ± 1.0 | 1000 |

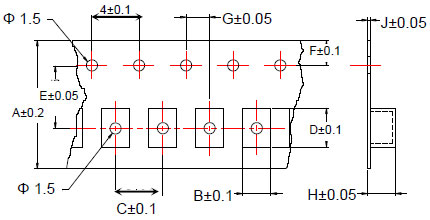

Embossed Plastic Tape Specifications (Unit : mm)

| Type | A | B | C | D | E | F | G | H | J |

|---|---|---|---|---|---|---|---|---|---|

| NL03 | 8 | 1.25 | 4 | 1.90 | 3.5 | 1.75 | 2 | 1.00 | 0.23 |

| NL05 | 8 | 1.85 | 4 | 2.55 | 3.5 | 1.75 | 2 | 1.45 | 0.23 |

| NL08 | 8 | 2.80 | 4 | 2.95 | 3.5 | 1.75 | 2 | 2.22 | 0.23 |

| NL10 | 8 | 2.96 | 4 | 3.60 | 3.5 | 1.75 | 2 | 2.40 | 0.23 |

| NL12 | 12 | 3.30 | 8 | 5.00 | 5.5 | 1.75 | 2 | 3.50 | 0.30 |

| NL20 | 16 | 5.35 | 12 | 6.10 | 7.5 | 1.75 | 2 | 5.50 | 0.35 |

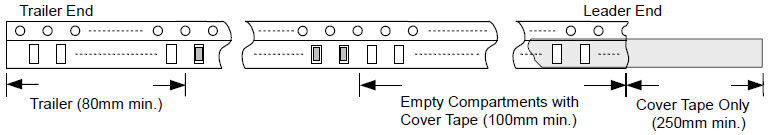

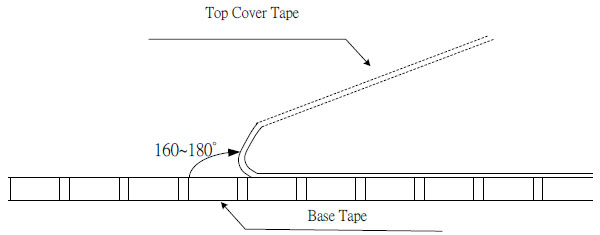

Leader / Trailer Tape

Cover Tape Peel Strength

The force for tearing off cover tape is 0.1 ~ 0.6 (N) in the arrow direction at the following conditions:

Resistor de precisión de película delgada 0.01%, TC2ppm, wirebondale, anti-corrosivo, MELF. Detección...

Lee mas

Inductores de chip cerámicos de alta frecuencia, tamaño pequeño hasta 01005. Inductor de película...

Lee mas

El capacitor cerámico multicapa ofrece alta tensión, alta frecuencia, bajo ruido, alta Q, bajo TCR....

Lee mas