AUTOMOTIVE APPLICATIONS

Thin film Precision resistor 0.01%, TC2ppm, wirebondale, Anti-Crossive, MELF. Current sensing, Metal...

Read MoreSMD high power , high saturation inductor, Ideal inductors for DC-DC converteres in all 4C products.

PD Series5022 ±20% 560μH 1.08 Ω 1.3A

| Size | Tolerance | Inductance | Test Condition | DCR (Ω) max. | IDC (A) |

|---|---|---|---|---|---|

| 5022 | ±20% | 560 | 100KHz, 0.1V | 1.08 | 1.3 |

| Type | Tape Size | Parts Per Reel | |

|---|---|---|---|

| W | P | 13" | |

| PD1608 | 16 | 8 | 2000 |

| PD3308 | 24 | 12 | 1000 |

| PD3316 | 24 | 12 | 1000 |

| PD3340 | 24 | 16 | 225 |

| PD5022 | 32 | 20 | 250 |

General

| Item | Specification |

|---|---|

| Shelf Storage conditions | Temperature range: 15 ~ 28°C; Humidity: < 80% relative humidity. Recommended product should be used within one year from the time of delivery. |

Environmental Test

| Item | Specification | Test Conditions / Test Methods |

|---|---|---|

| High temperature Storage test | No case deformation or change in appearance. Δ L/L ≤10% |

Temperature 85 ± 2°C, Time: 96 ± 2 hours, Tested after 1hour at room temperature. |

| Low temperature Storage test | Temperature -25 ± 2°C, Time: 96 ± 2 hours, Tested after 1hour at room temperature. |

|

| Humidity test | Temperature 40 ± 2°C, 90 ~ 95% relative humidity Time: 96 ± 2 hours Tested after 1hour at room temperature. |

|

| Thermal shock test | First -25°C 30minutes then 25°C 10 minutes last 85°C 30 minutes, as 1 cycle. Go through 5 cycles. Tested after 1 hour at room temperature. |

Mechanical Test

| Item | Specification | Test Conditions / Test Methods |

|---|---|---|

| Solderability test | Terminal area must have 90% minimum solder coverage. | Dip pads in flux then dip in solder pot (SnCuNi) at 245 ± 5°C for 3 seconds. |

| Resistance to Soldering Heat | No case deformation or change in appearance. | Flux should cover the whole of the sample before heating, then be preheated for about 2 minutes over temperature of 130 ~ 150°C. Immersing to 260 ± 5°C for 10 seconds. |

| Vibration test | No case deformation or change in appearance. Δ L/L ≤10% |

Apply frequency 10 ~ 55Hz. 1.5mm amplitude in each of perpendicular direction for 2 hours. |

| Shock resistance | Drop down with 981m/s² (100G) shock attitude upon a rubber block method shock testing machine, for 1 time. In each of three orientations. |

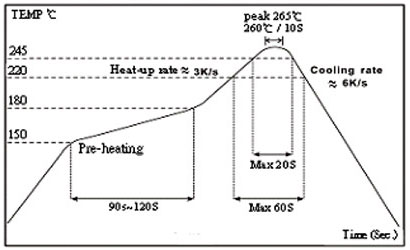

The Condition Of Reflow (Recommendation):

Thin film Precision resistor 0.01%, TC2ppm, wirebondale, Anti-Crossive, MELF. Current sensing, Metal...

Read More

Ceramic high frequency chip inductors, small size to 01005. Thin film, multilayer, wirewound , ferrite...

Read More

Multilayer Ceramic capacitor offers high Voltage, high frequency, low noise, High Q, Low TCR. NPO, X7R,...

Read More