AUTOMOTIEVE TOEPASSINGEN

Dunne film precisieweerstand 0,01%, TC2ppm, draadverbinding, anti-corrosief, MELF. Stroomdetectie, metaal,...

Lees verderChip common mode filter is een kleine chipinductor met ferrietkern en twee soorten draad gewonden. Zeer effectief in ruisonderdrukking, hoge gemeenschappelijke modusimpedantie in het ruisband en lage differentiële modusimpedantie in het signaalband, lage differentiële modusimpedantie met hoge koppelingsfactor. Er is bijna geen vervorming bij hoge snelheidssignalen. Typisch voor EMI-stralingsruisonderdrukking voor elektronische apparaten.

CM Series1206 ±20% 2200μH 1.2 Ω 200mA 125V 10MΩ min.

| Grootte | Tolerantie | Inductantie | Testconditie | DCR (Ω) max. | IDC (mA) | Nominale spanning | Doorlaatspanning Vdc (V) | Isolatieweerstand (MΩ) min. |

|---|---|---|---|---|---|---|---|---|

| 1206 | ±20% | 2200 | 100MHz | 1.2 | 200 | 50 | 125 | 10 |

Electrical Performance Test

| Items | Requirement | Test Conditions / Test Methods |

|---|---|---|

| Impedance | Refer to standard electrical characteristic spec. Component should not be damaged | LCR Meter HP 4291B |

| DC Resistance DCR | Micro-Ohm meter (GOM-801G) | |

| Withstand Voltage (VDC) | Test Voltage: 2.5 Times Rated Voltage Testing Time: 60 seconds Charge Current: 0.5mA | |

| Rated Voltage (VDC) | Test Voltage: Rated Voltage Testing Time: 1 to 5 seconds Charge Current: 1mA | |

| Insulation Resistance (I.R) | Charge Current: 1minute 10M ohm min. |

Mechanical Performance Test

| Items | Requirement | Test Conditions / Test Methods |

|---|---|---|

| Component Adhesion (Push Test) | Base: 0805≧2 Lbs Cover: 0805≧1 Lbs Base: 1206≧4 Lbs Cover: 1206≧2 Lbs | The component should be soldered (232°C± 5°C for 10 sec.) to tinned copper substrate Applied force gauge to the side of component It must withstand force of 2 or 4 pounds without failure of the component. |

| Drop | Component should not be damaged | Dropping chip by each side and corner. Drop 10 times in total Drop height: 100 cm Drop weight: 125 g |

| Solderability | The terminal should at least be 90% covered with solder | The component shall be dipped in a melted solder bath at 245 ±5℃ for 3 seconds |

| Vibration Test (Low Frequency) | Component should not be damaged | 1. Amplitude: 1.5 m/m 2. Frequency: 10-55-10Hz (1min.) 3. Direction: X, Y, Z 4. Duration: 2 Hrs/X, Y, Z |

Climatic Test

| Items | Requirement | Test Conditions / Test Methods |

|---|---|---|

| Low Temperature Storage | Impedance change: Within± 20% Without distinct damage in appearance | 1. Temp: -40 ±2°C 2. Time: 1000±48 Hours 3. Component should be tested after 1hour at room temperature |

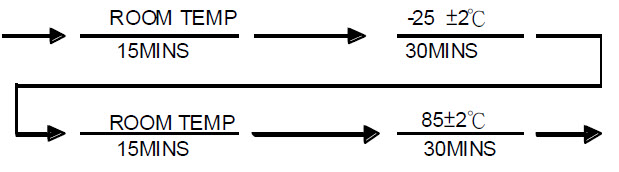

| Thermal Shock |  Total: 5 Cycles | |

| High Temperature Storage | 1. Temp: 85 ± 2°C 2. Time: 1000 ± 48 Hours 3. Component should be tested after 1hour at room temperature | |

| Humidity | 1. Temp: 40 ± 2°C 2. R.H. : 90 ~ 95% 3. Time: 48 ±2 Hours | |

| High Temperature Load Life | There should be no evidence of short or open circuit | 1. Temp: 85 ± 2°C 2. Time: 96 ± 12 Hours 3. Load: Allowed DC Current |

| Low Temperature Load Life | 1. Temp: -40 ± 2°C 2. Time: 96 ± 12 Hours 3. Load: Allowed DC Current |

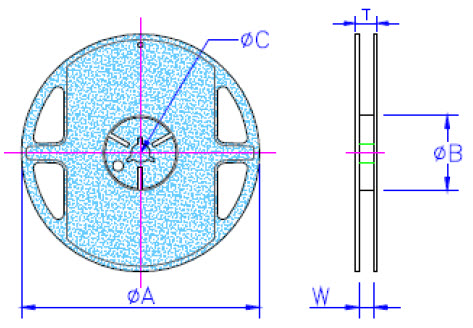

Packaging Quantity & Reel Specifications

| Type | ΦA | ΦB | ΦC | W | T | Quantity (EA) |

|---|---|---|---|---|---|---|

| CMH05 | 178±2.0 | 60±0.5 | 13±0.3 | 9±0.3 | 11.4±1.0 | 2000 |

| CMH06 | 178±2.0 | 60±0.5 | 13±0.3 | 9±0.3 | 11.4±1.0 | 2000 |

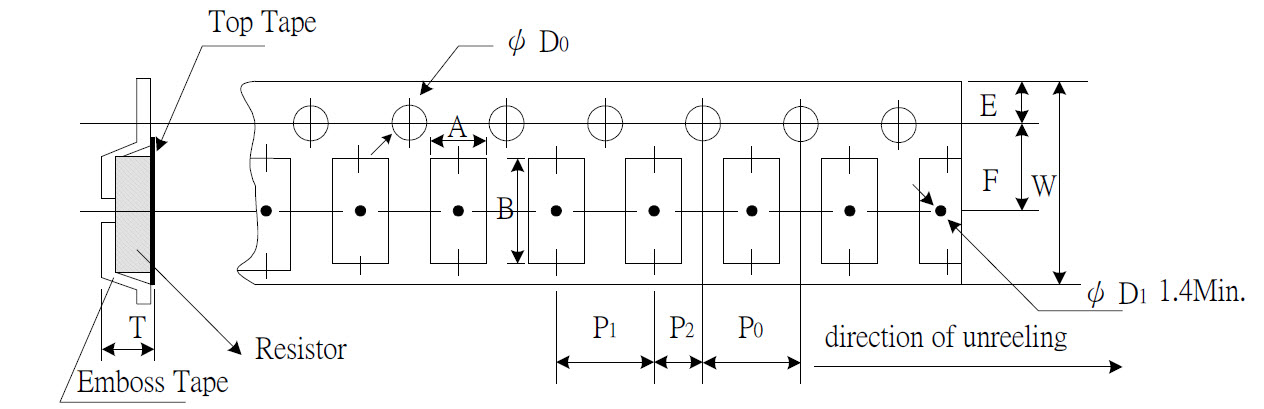

Embossed Plastic Tape Specifications

| Type | A (mm) | B (mm) | W (mm) | E (mm) | F (mm) | P0 (mm) | P1 (mm) | P2 (mm) | ΦD0 (mm) | T (mm) |

|---|---|---|---|---|---|---|---|---|---|---|

| CMH05 | 1.40±0.10 | 2.55±0.05 | 8.0±0.20 | 1.75±0.10 | 3.5±0.10 | 4.00±0.10 | 4.00±0.10 | 2.00±0.10 | 1.50+0.10 | 1.35±0.10 |

| CMH06 | 1.90±0.10 | 3.50±0.05 | 8.0±0.20 | 1.75±0.10 | 3.5±0.10 | 4.00±0.10 | 4.00±0.10 | 2.00±0.10 | 1.50+0.10 | 2.10±0.10 |

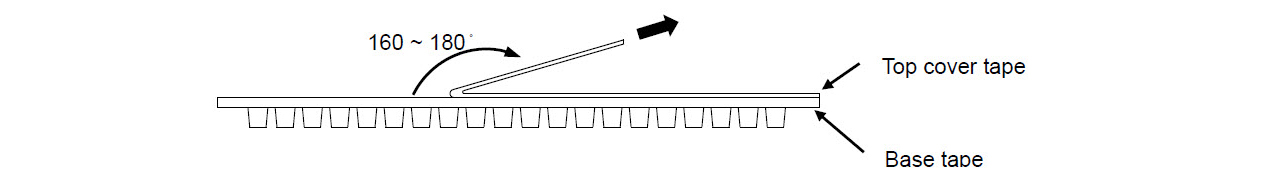

Peel-off Force

The force for tearing off cover tape is 0.05~0.69 (N) in the arrow direction at the following conditions:

Temperature: 5 ~ 35°C

Humidity: 45 ~ 85%

Atmospheric pressure: 860 ~ 1060hpa

Dunne film precisieweerstand 0,01%, TC2ppm, draadverbinding, anti-corrosief, MELF. Stroomdetectie, metaal,...

Lees verder

Keramische hoge frequentie chipinductoren, kleine maat tot 01005. Dunne film, multilayer, draadgewonden,...

Lees verder

Multilayer keramische condensator biedt hoge spanning, hoge frequentie, lage ruis, hoge Q, lage TCR....

Lees verder