와이어 권선형 전력 인덕터

MLP04MTR68

와이어 권선 페라이트 칩 고전력 인덕터, 소형, 폐쇄형 자기 회로로 크로스토크를 방지하며, 고밀도 설치 및 리플로우 납땜에 적합합니다. 모든 종류의 전자 기기, 컴퓨팅, 변환기에 사용됩니다.

MLP Series1004 ±20% 0.68μH 0.044 Ω 3.87A 3.06A

| 크기 | 허용오차 | 인덕턴스 | 테스트 조건 | DCR (Ω) 최대. | I sat (A) 최대. | I rms (A) 최대. |

|---|---|---|---|---|---|---|

| 1004 | ±20% | 0.68 | 1MHz, 1V | 0.044 | 3.87 | 3.06 |

환경 특성

Electrical Performance Test

| Item | Requirement | Test Method |

|---|---|---|

| Inductance | Refer to standard electrical characteristic spec. | HP4285A |

| DC Resistance RDC | micro-ohm meter. | |

| Isat | DC current will cause a 30% inductance reduction form initial value. | |

| Irms | DC current will cause coil temp. rising to 40℃ whichever is smaller. |

Mechanical Performance Test

| Item | Requirement | Test Method |

|---|---|---|

| Resistance to Soldering Heat | Appearance: No damage More than 95% of the terminal. Electrode should be covered with solder. Inductance: within ± 20% of initial value |

Flux: Rosin Solder Temperature: 260 ± 5°C Immersion Time: 10 ± 1 sec. |

| Adhesive Test | No mechanical damage Soldering the products on PCB after the pulling test force>5N |

Reflow temperature: 245°C it shall be soldered on the substrate applying direction parallel to the substrate Apply force(F): 5 N Test time: 10 sec |

| Temperature Cycle | No mechanical damage Inductance: within ± 20% of initial value |

Temperature: -50 ~ 125°C for 30 minutes each Cycle: 500cycles Measurement: at ambient temperature 24 hours after test completion |

| Dry Heat Test | Temperature: 85 ± 2°C Testing time: 500 hrs Applied current: full rated current Measurement: at ambient temperature 24 hours after test completion |

|

| Humidity Test | Temperature: 60 ± 2°C, Humidity: 90 ~ 95% RH Testing time: 500 hrs Applied current: full rated current Measurement: at ambient temperature 24 hours after test completion |

☑Storage Temperature: 5~40°C ; Humidity:<65%RH

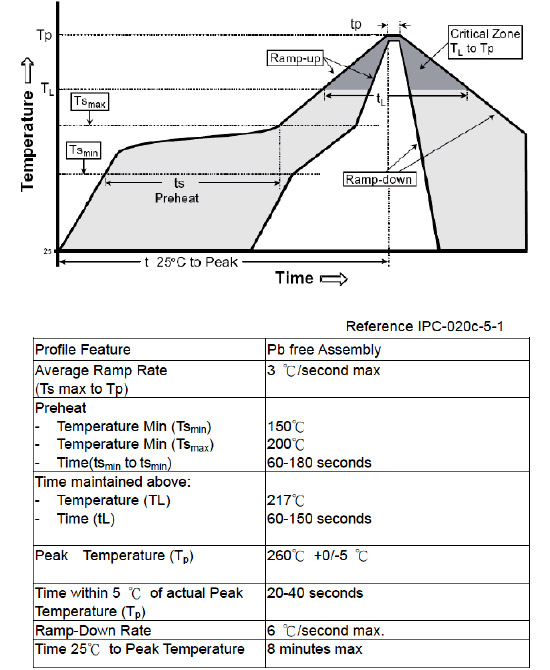

리플로우

Recommendable Reflow Soldering

포장

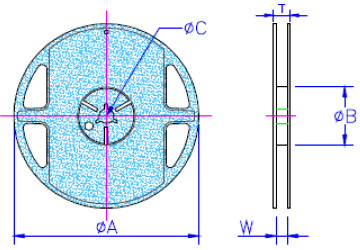

Reel Specifications (Unit: mm)

| Type | A | B | C | W | T | Quantity (EA) |  |

|---|---|---|---|---|---|---|---|

| MLP03 | 178 ± 1 | 60.0 + 0.5 | 13.0 ± 0.2 | 9.00 ± 0.5 | 12.0 ± 0.15 | 3,000 | |

| MLP05 | 178 ± 1 | 60.0 + 0.5 | 13.0 ± 0.2 | 9.00 ± 0.5 | 12.0 ± 0.15 | 3,000 | |

| MLP(H)06 | 178 ± 1 | 60.0 + 0.5 | 13.0 ± 0.2 | 9.00 ± 0.5 | 12.0 ± 0.15 | 3,000 | |

| MLP(H)04 | 178 ± 1 | 60.0 + 0.5 | 13.0 ± 0.2 | 9.00 ± 0.5 | 12.0 ± 0.15 | 3,000 | |

| MLP(H)08 | 178 ± 1 | 60.0 + 0.5 | 13.0 ± 0.2 | 9.00 ± 0.5 | 12.0 ± 0.15 | 3,000 | |

| MLP10 | 178 ± 1 | 60.0 + 0.5 | 13.0 ± 0.2 | 9.00 ± 0.5 | 12.0 ± 0.15 | 3,000 |

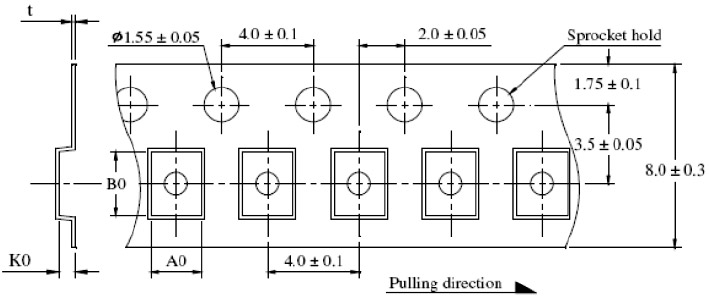

Tape Specifications (Unit: mm)

| Type | A0 | B0 | K0 | t |  |

|---|---|---|---|---|---|

| MLP03 | 1.52 ± 0.10 | 2.35 ± 0.10 | 0.87 ± 0.05 | 0.22 ± 0.05 | |

| MLP05 | 1.45 ± 0.10 | 2.20 ± 0.10 | 1.12 ± 0.10 | 0.22 ± 0.05 | |

| MLP06 | 1.80 ± 0.10 | 2.20 ± 0.10 | 1.15 ± 0.10 | 0.22 ± 0.05 | |

| MLPH06 | 1.82 ± 0.05 | 2.23 ± 0.05 | 1.15 ± 0.05 | 0.22 ± 0.05 | |

| MLP04 | 2.50 ± 0.10 | 3.00 ± 0.10 | 1.60 ± 0.10 | 0.25 ± 0.05 | |

| MLPH04 | 2.25 ± 0.05 | 2.80 ± 0.10 | 1.35 ± 0.10 | 0.22 ± 0.05 | |

| MLP08 | 2.50 ± 0.10 | 3.00 ± 0.10 | 1.60 ± 0.10 | 0.25 ± 0.05 | |

| MLPH08 | 2.25 ± 0.05 | 2.80 ± 0.10 | 1.35 ± 0.10 | 0.22 ± 0.05 | |

| MLP10 | 2.80 ± 0.10 | 3.45 ± 0.10 | 1.34 ± 0.10 | 0.23 ± 0.05 |

코드

- R68

베스트 판매

주요 제품