AUTOMOTIVE APPLICATIONS

Thin film Precision resistor 0.01%, TC2ppm, wirebondale, Anti-Crossive, MELF. Current sensing, Metal...

Read MoreWire wound chip ferrite inductor, high current, molded and open type are available. small size down to 0603 , very strong solderability by flow soldering or soldering iron , wave soldering. Highly resistanct to mechanical shocks and pressure. Highly reliable in environments of sudden temp change and humidity. super Q characteristics.

NL Series1812 ±10% 6.8μH 0.35 Ω 600A 10 28

| Size | Tolerance | Inductance | Test Condition | DCR (Ω) max. | IDC (A) | Q | SRF |

|---|---|---|---|---|---|---|---|

| 1812 | ±10% | 6.8 | 7.96MHz | 0.35 | 600 | 10 | 28 |

NL05 Wound Chip Inductors (Ferrite / Open Type) / Low Profile Type

| Codes | Inductance (uH) | Tolerance | Q min. | Test Freq. (MHz) | SRF (MHz) min. | DCR (Ω) max. | IDC (mA) max. |

|---|---|---|---|---|---|---|---|

| 1R0 | 1.0 | ± 5, ± 10% | 15 | L: 7.96 / Q: 25.2 | 115 | 0.90 | 450 |

| 3R3 | 3.3 | ± 5, ± 10% | 13 | 7.96 | 70 | 1.40 | 450 |

| 4R7 | 4.7 | ± 5, ± 10% | 15 | 7.96 | 65 | 1.90 | 400 |

| 6R8 | 6.8 | ± 5, ± 10% | 15 | 7.96 | 41 | 2.40 | 400 |

| 100 | 10 | ± 5, ± 10% | 14 | 7.96 | 31 | 2.70 | 400 |

| 150 | 15 | ± 5, ± 10% | 12 | 7.96 | 28 | 5.00 | 300 |

| 220 | 22 | ± 5, ± 10% | 10 | 7.96 | 25 | 6.00 | 250 |

NL03 Wound Chip Inductors (Ferrite / Open Type) / Large Current Type

| Codes | Inductance (uH) | Tolerance | Q min. | Test Freq. (MHz) | SRF (MHz) min. | DCR (Ω) max. | IDC (mA) max. | Color Code |

|---|---|---|---|---|---|---|---|---|

| 47N | 0.047 | ± 10% | 12 | 7.9 | 2000 | 0.075 | 1800 | White |

| 51N | 0.051 | ± 10% | 12 | 7.9 | 1500 | 0.075 | 1800 | Violet |

| 56N | 0.056 | ± 10% | 7 | 7.9 | 1500 | 0.095 | 2200 | Blue |

| 68N | 0.068 | ± 10% | 10 | 7.9 | 1500 | 0.12 | 2200 | Gray |

| 72N | 0.072 | ± 10% | 12 | 7.9 | 1500 | 0.12 | 2200 | Brown |

| R10 | 0.10 | ± 10% | 12 | 7.9 | 1150 | 0.13 | 2200 | Black |

| R12 | 0.12 | ± 5, ± 10% | 12 | 7.9 | 1100 | 0.15 | 1900 | Orange |

| R15 | 0.15 | ± 5, ± 10% | 15 | 7.9 | 1050 | 0.15 | 1800 | Brown |

| R18 | 0.18 | ± 5, ± 10% | 15 | 7.9 | 950 | 0.15 | 1800 | Green |

| R22 | 0.22 | ± 5, ± 10% | 15 | 7.9 | 900 | 0.30 | 1300 | Red |

| R24 | 0.24 | ± 5, ± 10% | 15 | 7.9 | 850 | 0.16 | 1700 | Green |

| R27 | 0.27 | ± 5, ± 10% | 15 | 7.9 | 835 | 0.30 | 1400 | Yellow |

| R33 | 0.33 | ± 5, ± 10% | 15 | 7.9 | 725 | 0.40 | 1300 | Orange |

| R36 | 0.36 | ± 5, ± 10% | 15 | 7.9 | 720 | 0.41 | 1300 | Green |

| R39 | 0.39 | ± 5, ± 10% | 15 | 7.9 | 680 | 0.41 | 1200 | Blue |

| R47 | 0.47 | ± 5, ± 10% | 15 | 7.9 | 640 | 0.43 | 1200 | Black |

| R56 | 0.56 | ± 5, ± 10% | 15 | 7.9 | 630 | 0.44 | 1200 | Brown |

| R65 | 0.65 | ± 5, ± 10% | 15 | 7.9 | 510 | 0.52 | 1000 | Blue |

| R68 | 0.68 | ± 5, ± 10% | 15 | 7.9 | 510 | 0.52 | 1000 | Red |

| R78 | 0.78 | ± 5, ± 10% | 15 | 7.9 | 465 | 0.63 | 990 | Orange |

| R82 | 0.82 | ± 5, ± 10% | 15 | 7.9 | 460 | 0.69 | 990 | Yellow |

| R90 | 0.90 | ± 5, ± 10% | 15 | 7.9 | 350 | 0.81 | 950 | Black |

| 1R0 | 1.0 | ± 5, ± 10% | 15 | 7.9 | 320 | 0.81 | 850 | Green |

| 1R2 | 1.2 | ± 5, ± 10% | 15 | 7.9 | 270 | 0.87 | 850 | Blue |

| 1R5 | 1.5 | ± 5, ± 10% | 15 | 7.9 | 230 | 0.96 | 830 | Violet |

| 1R8 | 1.8 | ± 5, ± 10% | 15 | 7.9 | 210 | 1.10 | 820 | Gray |

| 2R2 | 2.2 | ± 5, ± 10% | 15 | 7.9 | 115 | 1.20 | 720 | White |

| 2R7 | 2.7 | ± 5, ± 10% | 15 | 7.9 | 100 | 1.38 | 700 | Black |

| 3R0 | 3.0 | ± 5, ± 10% | 15 | 7.9 | 90 | 1.45 | 680 | Black |

| 3R3 | 3.3 | ± 5, ± 10% | 15 | 7.9 | 84 | 1.50 | 640 | Brown |

| 3R9 | 3.9 | ± 5, ± 10% | 15 | 7.9 | 75 | 1.50 | 630 | Red |

| 4R7 | 4.7 | ± 5, ± 10% | 15 | 7.9 | 67 | 2.10 | 530 | Orange |

| 5R6 | 5.6 | ± 5, ± 10% | 15 | 7.9 | 55 | 2.37 | 510 | Yellow |

| 6R8 | 6.8 | ± 5, ± 10% | 15 | 7.9 | 48 | 3.10 | 490 | Green |

| 7R8 | 7.8 | ± 5, ± 10% | 15 | 7.9 | 40 | 3.35 | 420 | Blue |

| 8R2 | 8.2 | ± 5, ± 10% | 15 | 7.9 | 38 | 3.50 | 450 | Violet |

| 100 | 10 | ± 5, ± 10% | 15 | 7.9 | 32 | 4.46 | 370 | Gray |

| 150 | 15 | ± 5, ± 10% | 14 | 7.9 | 25 | 9.50 | 240 | White |

NL05 Wire Wound Chip Inductors (Ferrite / Open Type) / Large Current Type

| Codes | Inductance (uH) | Tolerance | Q min. | Test Freq. (MHz) | SRF (MHz) min. | DCR (Ω) max. | IDC (mA) max. | Color Code |

|---|---|---|---|---|---|---|---|---|

| R10 | 0.10 | ± 10, ± 20% | 9 | 7.9 | 1700 | 0.091 | 2400 | Black |

| R15 | 0.15 | ± 10, ± 20% | 12 | 7.9 | 1500 | 0.104 | 1900 | Brown |

| R22 | 0.22 | ± 10, ± 20% | 12 | 7.9 | 1200 | 0.130 | 1700 | Red |

| R33 | 0.33 | ± 10, ± 20% | 12 | 7.9 | 900 | 0.156 | 1400 | Orange |

| R47 | 0.47 | ± 10, ± 20% | 14 | 7.9 | 850 | 0.156 | 1400 | Blue |

| R56 | 0.56 | ± 10, ± 20% | 14 | 7.9 | 360 | 0.195 | 1200 | Violet |

| R68 | 0.68 | ± 10, ± 20% | 14 | 7.9 | 290 | 0.195 | 1200 | Gray |

| R82 | 0.82 | ± 10, ± 20% | 14 | 7.9 | 208 | 0.195 | 1100 | White |

| 1R0 | 1.00 | ± 10, ± 20% | 14 | 7.9 | 208 | 0.169 | 1100 | Black |

| 1R2 | 1.20 | ± 10, ± 20% | 14 | 7.9 | 159 | 0.208 | 960 | Red |

| 1R5 | 1.50 | ± 10, ± 20% | 14 | 7.9 | 159 | 0.221 | 920 | Brown |

| 1R8 | 1.80 | ± 10, ± 20% | 14 | 7.9 | 112 | 0.260 | 860 | Orange |

| 2R2 | 2.20 | ± 10, ± 20% | 13 | 7.9 | 87 | 0.286 | 740 | Red |

| 2R7 | 2.70 | ± 10, ± 20% | 13 | 7.9 | 72 | 0.325 | 680 | Yellow |

| 3R3 | 3.30 | ± 10, ± 20% | 12 | 7.9 | 70 | 0.364 | 620 | Orange |

| 3R9 | 3.90 | ± 10, ± 20% | 14 | 7.9 | 61 | 0.494 | 580 | Green |

| 4R7 | 4.70 | ± 10, ± 20% | 14 | 7.9 | 51 | 0.559 | 520 | Yellow |

| 5R6 | 5.60 | ± 10, ± 20% | 12 | 7.9 | 47 | 0.650 | 480 | Blue |

| 6R8 | 6.80 | ± 10, ± 20% | 14 | 7.9 | 46 | 0.884 | 420 | Green |

| 8R2 | 8.20 | ± 10, ± 20% | 13 | 7.9 | 33 | 0.949 | 400 | Violet |

| 100 | 10 | ± 5, ± 10,± 20% | 14 | 2.5 | 31 | 1.105 | 360 | Blue |

| 120 | 12 | ± 5, ± 10,± 20% | 14 | 2.5 | 30 | 1.17 | 340 | Gray |

| 150 | 15 | ± 5, ± 10,± 20% | 15 | 2.5 | 28 | 1.82 | 300 | Violet |

| 180 | 18 | ± 5, ± 10,± 20% | 15 | 2.5 | 27 | 2.01 | 280 | White |

| 220 | 22 | ± 5, ± 10,± 20% | 15 | 2.5 | 20 | 2.288 | 240 | Gray |

| 270 | 27 | ± 5, ± 10,± 20% | 15 | 2.5 | 17 | 2.60 | 220 | Black |

| 330 | 33 | ± 5, ± 10,± 20% | 15 | 2.5 | 17 | 3.055 | 200 | White |

| 390 | 39 | ± 5, ± 10,± 20% | 14 | 2.5 | 15 | 4.355 | 180 | Brown |

| 470 | 47 | ± 5, ± 10,± 20% | 14 | 2.5 | 15 | 4.42 | 160 | Black |

| 560 | 56 | ± 5, ± 10,± 20% | 14 | 2.5 | 10 | 5.746 | 150 | Yellow |

| 680 | 68 | ± 5, ± 10,± 20% | 14 | 2.5 | 10 | 5.785 | 140 | Brown |

| 820 | 82 | ± 5, ± 10,± 20% | 14 | 2.5 | 10 | 9.75 | 100 | Orange |

| 101 | 100 | ± 5, ± 10,± 20% | 10 | 1 | 9 | 9.75 | 100 | Red |

| 221 | 220 | ± 5, ± 10,± 20% | 8 | 1 | 4 | 30.03 | 70 | Blue |

NL08 Wound Chip Inductors (Ferrite / Open Type) / Large Current Type

| Codes | Inductance (uH) | Tolerance | Q typ. | Test Freq. (MHz) | SRF (MHz) min. | DCR (Ω) max. | IDC (mA) max. | Color Code | ||

|---|---|---|---|---|---|---|---|---|---|---|

| 1st | 2nd | 3rd | ||||||||

| 78N | 0.078 | ± 5, ± 10% | 19 | 7.9 | 1000 | 0.042 | 3200 | Black | Violet | Gray |

| R10 | 0.10 | ± 5, ± 10% | 35 | 25 | 1500 | 0.05 | 3200 | Brown | Red | Brown |

| R22 | 0.22 | ± 5, ± 10% | 35 | 25 | 800 | 0.15 | 2900 | Red | Red | Brown |

| R39 | 0.39 | ± 5, ± 10% | 35 | 25 | 460 | 0.20 | 2100 | Orange | White | Brown |

| R47 | 0.47 | ± 10% | 35 | 25 | 460 | 0.20 | 2100 | Yellow | Violet | Brown |

| R56 | 0.56 | ± 5, ± 10% | 35 | 25 | 360 | 0.26 | 1800 | Green | Blue | Brown |

| R68 | 0.68 | ± 5, ± 10% | 35 | 25 | 400 | 0.30 | 1700 | Blue | Gray | Brown |

| R82 | 0.82 | ± 5, ± 10% | 35 | 25 | 360 | 0.35 | 1400 | Gray | Red | Brown |

| 1R0 | 1.0 | ± 10% | 32 | 7.9 | 340 | 0.34 | 1700 | Brown | Black | Red |

| 1R1 | 1.1 | ± 10% | 25 | 7.9 | 300 | 0.34 | 1500 | Brown | Brown | Red |

| 1R2 | 1.2 | ± 5, ± 10% | 25 | 7.9 | 300 | 0.25 | 1600 | Brown | Red | Red |

| 1R5 | 1.5 | ± 5, ± 10% | 32 | 7.9 | 230 | 0.42 | 1200 | Brown | Green | Red |

| 1R8 | 1.8 | ± 5, ± 10% | 27 | 7.9 | 180 | 0.45 | 1100 | Brown | Gray | Red |

| 2R2 | 2.2 | ± 5, ± 10% | 27 | 7.9 | 140 | 0.50 | 1100 | Red | Red | Red |

| 2R7 | 2.7 | ± 5, ± 10% | 27 | 7.9 | 130 | 0.55 | 1000 | Red | Violet | Red |

| 3R3 | 3.3 | ± 5, ± 10% | 27 | 7.9 | 125 | 0.60 | 1000 | Orange | Orange | Red |

| 3R9 | 3.9 | ± 5, ± 10% | 27 | 7.9 | 100 | 0.80 | 990 | Orange | White | Red |

| 4R7 | 4.7 | ± 5, ± 10% | 30 | 7.9 | 90 | 0.90 | 880 | Yellow | Violet | Red |

| 5R6 | 5.6 | ± 5, ± 10% | 27 | 7.9 | 60 | 1.00 | 850 | Green | Blue | Red |

| 6R8 | 6.8 | ± 5, ± 10% | 27 | 7.9 | 60 | 1.05 | 840 | Blue | Gray | Red |

| 8R2 | 8.2 | ± 5, ± 10% | 25 | 7.9 | 55 | 1.20 | 810 | Gray | Red | Red |

| 100 | 10 | ± 5, ± 10% | 23 | 2.5 | 55 | 1.55 | 700 | Brown | Black | Orange |

| 120 | 12 | ± 5, ± 10% | 23 | 2.5 | 36 | 2.10 | 580 | Brown | Red | Orange |

| 150 | 15 | ± 5, ± 10% | 23 | 2.5 | 36 | 2.38 | 580 | Brown | Green | Orange |

| 180 | 18 | ± 5, ± 10% | 23 | 2.5 | 32 | 2.50 | 520 | Brown | Gray | Orange |

| 220 | 22 | ± 5, ± 10% | 23 | 2.5 | 29 | 2.92 | 500 | Red | Red | Orange |

| 270 | 27 | ± 10% | 23 | 2.5 | 22 | 3.70 | 450 | Red | Violet | Orange |

| 330 | 33 | ± 5, ± 10% | 23 | 2.5 | 21 | 4.10 | 420 | Orange | Orange | Orange |

| 390 | 39 | ± 5, ± 10% | 18 | 2.5 | 15 | 5.50 | 340 | Orange | White | Orange |

| 470 | 47 | ± 5, ± 10% | 23 | 2.5 | 17 | 7.80 | 310 | Yellow | Violet | Orange |

| 680 | 68 | ± 5, ± 10% | 20 | 2.5 | 9 | 11.5 | 220 | Blue | Gray | Orange |

| 101 | 100 | ± 5, ± 10% | 13 | 1 | 4 | 13.2 | 210 | Brown | Black | Yellow |

| 151 | 150 | ± 5, ± 10% | 13 | 1 | 3 | 22.5 | 170 | Brown | Green | Yelloe |

| 221 | 220 | ± 5, ± 10% | 13 | 1 | 3 | 26.5 | 160 | Red | Red | Yellow |

| 271 | 270 | ± 5, ± 10% | 13 | 1 | 2 | 32.0 | 135 | Red | Violet | Yellow |

| 331 | 330 | ± 5, ± 10% | 13 | 1 | 2 | 32.5 | 130 | Orange | Orange | Yellow |

NL10 Wire Wound Chip Inductors (Ferrite / Molding Type) / Large Current Type

| Codes | Inductance (uH) | Tolerance | Q min. | Test Freq. (MHz) | SRF (MHz) typ. | DCR (Ω) max. | IDC (mA) max. |

|---|---|---|---|---|---|---|---|

| 1R0 | 1.0 | ± 5%,± 20% | 10 | 7.96 | 145 | 0.156 | 770 |

| 1R5 | 1.5 | ± 5%,± 20% | 10 | 7.96 | 100 | 0.195 | 580 |

| 2R2 | 2.2 | ± 5%,± 20% | 10 | 7.96 | 80 | 0.260 | 480 |

| 3R3 | 3.3 | ± 5%,± 20% | 10 | 7.96 | 60 | 0.325 | 400 |

| 4R7 | 4.7 | ± 5%,± 20% | 10 | 7.96 | 50 | 0.520 | 320 |

| 6R8 | 6.8 | ± 5%,± 20% | 10 | 7.96 | 40 | 0.650 | 280 |

| 100 | 10 | ± 5%,± 10% | 15 | 2.52 | 30 | 1.105 | 220 |

| 150 | 15 | ± 5%,± 10% | 15 | 2.52 | 27 | 1.690 | 180 |

| 220 | 22 | ± 5%,± 10% | 15 | 2.52 | 22 | 2.600 | 145 |

| 270 | 27 | ± 5%,± 10% | 15 | 2.52 | 19 | 3.000 | 125 |

| 330 | 33 | ± 5%,± 10% | 15 | 2.52 | 17 | 3.640 | 115 |

| 470 | 47 | ± 5%,± 10% | 20 | 2.52 | 15 | 5.460 | 105 |

| 680 | 68 | ± 5%,± 10% | 20 | 2.52 | 11 | 8.450 | 85 |

| 820 | 82 | ± 5%,± 10% | 20 | 2.52 | 10 | 8.710 | 80 |

| 101 | 100 | ± 5%,± 10% | 20 | 0.796 | 9 | 10.140 | 75 |

NL12 Wire Wound Chip Inductors (Ferrite / Molding Type) / Large Current Type

| Codes | Inductance (uH) | Tolerance | Q min. | Test Freq. (MHz) | SRF (MHz) typ. | DCR (Ω) max. | IDC (mA) max. |

|---|---|---|---|---|---|---|---|

| 1R0 | 1.0 | ± 5%,± 10% | 10 | 7.96 | 265 | 0.11 | 1050 |

| 1R2 | 1.2 | ± 5%,± 10% | 10 | 7.96 | 180 | 0.12 | 1000 |

| 1R5 | 1.5 | ± 5%,± 10% | 10 | 7.96 | 170 | 0.15 | 950 |

| 1R8 | 1.8 | ± 5%,± 10% | 10 | 7.96 | 105 | 0.16 | 900 |

| 2R2 | 2.2 | ± 5%,± 10% | 10 | 7.96 | 80 | 0.18 | 850 |

| 2R7 | 2.7 | ± 5%,± 10% | 10 | 7.96 | 60 | 0.20 | 800 |

| 3R3 | 3.3 | ± 5%,± 10% | 10 | 7.96 | 55 | 0.22 | 750 |

| 3R9 | 3.9 | ± 5%,± 10% | 10 | 7.96 | 45 | 0.24 | 700 |

| 4R7 | 4.7 | ± 5%,± 10% | 10 | 7.96 | 43 | 0.27 | 650 |

| 5R6 | 5.6 | ± 5%,± 10% | 10 | 7.96 | 40 | 0.30 | 650 |

| 6R8 | 6.8 | ± 5%,± 10% | 10 | 7.96 | 35 | 0.35 | 600 |

| 8R2 | 8.2 | ± 5%,± 10% | 10 | 7.96 | 30 | 0.40 | 600 |

| 100 | 10 | ± 5%,± 10% | 10 | 2.52 | 27 | 0.50 | 550 |

| 120 | 12 | ± 5%,± 10% | 10 | 2.52 | 25 | 0.60 | 500 |

| 150 | 15 | ± 5%,± 10% | 10 | 2.52 | 20 | 0.70 | 450 |

| 180 | 18 | ± 5%,± 10% | 10 | 2.52 | 19 | 0.80 | 400 |

| 220 | 22 | ± 5%,± 10% | 10 | 2.52 | 18 | 0.90 | 370 |

| 270 | 27 | ± 5%,± 10% | 10 | 2.52 | 16 | 1.20 | 330 |

| 330 | 33 | ± 5%,± 10% | 10 | 2.52 | 15 | 1.40 | 300 |

| 390 | 39 | ± 5%,± 10% | 10 | 2.52 | 13 | 1.60 | 280 |

| 470 | 47 | ± 5%,± 10% | 10 | 2.52 | 12 | 1.90 | 260 |

| 560 | 56 | ± 5%,± 10% | 10 | 2.52 | 10 | 2.20 | 240 |

| 680 | 68 | ± 5%,± 10% | 10 | 2.52 | 9.5 | 2.60 | 220 |

| 820 | 82 | ± 5%,± 10% | 10 | 2.52 | 8.5 | 3.50 | 200 |

| 101 | 100 | ± 5%,± 10% | 20 | 0.796 | 8.0 | 4.00 | 180 |

| 121 | 120 | ± 5%,± 10% | 20 | 0.796 | 7.0 | 4.50 | 160 |

| 151 | 150 | ± 5%,± 10% | 20 | 0.796 | 6.5 | 6.50 | 140 |

| 181 | 180 | ± 5%,± 10% | 20 | 0.796 | 6.0 | 7.50 | 120 |

| 221 | 220 | ± 5%,± 10% | 20 | 0.796 | 5.5 | 9.00 | 120 |

| 271 | 270 | ± 5%,± 10% | 20 | 0.796 | 5.0 | 11.0 | 100 |

| 331 | 330 | ± 5%,± 10% | 20 | 0.796 | 4.5 | 13.0 | 90 |

| 391 | 390 | ± 5%,± 10% | 20 | 0.796 | 4.0 | 14.0 | 85 |

| 471 | 470 | ± 5%,± 10% | 20 | 0.796 | 3.5 | 16.0 | 75 |

| 561 | 560 | ± 5%,± 10% | 20 | 0.796 | 3.0 | 21.0 | 70 |

| 681 | 680 | ± 5%,± 10% | 20 | 0.796 | 2.5 | 24.0 | 65 |

NL20 Wire Wound Chip Inductors (Ferrite / Molding Type) / Large Current Type

| Codes | Inductance (uH) | Tolerance | Q min. | Test Freq. (MHz) | SRF (MHz) min. | DCR (Ω) max. | IDC (mA) max. |

|---|---|---|---|---|---|---|---|

| 1R0 | 1.0 | ± 10,± 20% | 10 | 7.96 | 95 | 0.03 | 1800 |

| 1R2 | 1.2 | ± 10, ± 20% | 10 | 7.96 | 70 | 0.035 | 1700 |

| 1R5 | 1.5 | ± 10, ± 20% | 10 | 7.96 | 55 | 0.04 | 1600 |

| 1R8 | 1.8 | ± 10, ± 20% | 10 | 7.96 | 47 | 0.05 | 1400 |

| 2R2 | 2.2 | ± 10, ± 20% | 10 | 7.96 | 42 | 0.06 | 1300 |

| 2R7 | 2.7 | ± 10, ± 20% | 10 | 7.96 | 37 | 0.07 | 1200 |

| 3R3 | 3.3 | ± 10, ± 20% | 10 | 7.96 | 34 | 0.08 | 1120 |

| 3R9 | 3.9 | ± 10, ± 20% | 10 | 7.96 | 32 | 0.09 | 1050 |

| 4R7 | 4.7 | ± 10, ± 20% | 10 | 7.96 | 29 | 0.11 | 950 |

| 5R6 | 5.6 | ± 10, ± 20% | 10 | 7.96 | 26 | 0.13 | 880 |

| 6R8 | 6.8 | ± 10, ± 20% | 10 | 7.96 | 24 | 0.15 | 810 |

| 8R2 | 8.2 | ± 10, ± 20% | 10 | 7.96 | 22 | 0.18 | 750 |

| 100 | 10 | ± 10, ± 20% | 10 | 2.52 | 19 | 0.21 | 690 |

| 120 | 12 | ± 10, ± 20% | 10 | 2.52 | 17 | 0.25 | 630 |

| 150 | 15 | ± 10, ± 20% | 10 | 2.52 | 16 | 0.30 | 580 |

| 180 | 18 | ± 10, ± 20% | 10 | 2.52 | 14 | 0.36 | 530 |

| 220 | 22 | ± 5, ± 10% | 10 | 2.52 | 13 | 0.43 | 480 |

| 270 | 27 | ± 5, ± 10% | 10 | 2.52 | 11.5 | 0.52 | 440 |

| 330 | 33 | ± 5, ± 10% | 10 | 2.52 | 10.5 | 0.62 | 400 |

| 390 | 39 | ± 5, ± 10% | 10 | 2.52 | 9.5 | 0.72 | 370 |

| 470 | 47 | ± 5, ± 10% | 10 | 2.52 | 8.5 | 0.85 | 340 |

| 560 | 56 | ± 5, ± 10% | 10 | 2.52 | 7.8 | 1.00 | 310 |

| 680 | 68 | ± 5, ± 10% | 10 | 2.52 | 7.0 | 1.2 | 290 |

| 820 | 82 | ± 5, ± 10% | 10 | 2.52 | 6.4 | 1.4 | 270 |

| 101 | 100 | ± 5, ± 10% | 20 | 0.796 | 6.0 | 1.6 | 250 |

| 121 | 120 | ± 5, ± 10% | 20 | 0.796 | 5.4 | 1.9 | 230 |

| 151 | 150 | ± 5, ± 10% | 20 | 0.796 | 4.8 | 2.2 | 210 |

| 181 | 180 | ± 5, ± 10% | 20 | 0.796 | 4.4 | 2.8 | 190 |

| 221 | 220 | ± 5, ± 10% | 20 | 0.796 | 3.9 | 3.4 | 170 |

| 271 | 270 | ± 5, ± 10% | 20 | 0.796 | 3.6 | 4.2 | 155 |

| 331 | 330 | ± 5, ± 10% | 20 | 0.796 | 3.2 | 4.9 | 140 |

| 391 | 390 | ± 5, ± 10% | 20 | 0.796 | 2.9 | 5.8 | 130 |

| 471 | 470 | ± 5, ± 10% | 20 | 0.796 | 2.6 | 7.0 | 120 |

| 561 | 560 | ± 5, ± 10% | 20 | 0.796 | 2.4 | 8.5 | 110 |

| 681 | 680 | ± 5, ± 10% | 20 | 0.796 | 2.2 | 10 | 100 |

| 821 | 820 | ± 5, ± 10% | 20 | 0.796 | 2.0 | 13 | 90 |

| 102 | 1000 | ± 5, ± 10% | 20 | 0.252 | 1.8 | 15 | 85 |

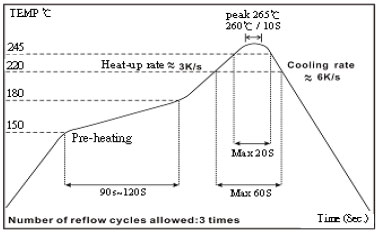

Electrical Performance Test

| Item | Requirement | Test Method |

|---|---|---|

| Inductance | Refer to standard electrical characteristic spec. | HP4291 or HP4284 |

| Q | HP4291 or HP4284 | |

| SRF | HP4291 | |

| DC Resistance DCR | Agilent 34401A | |

| Rated Current IDC | Applied the current to coils, The inductance change should be less than 10% to initial value. |

Mechanical Performance Test

| Item | Requirement | Test Method |

|---|---|---|

| Solderability | The electrodes shall be at least 90% covered with new solder coating | Lead-free inductor: after fluxing (alpha 100 or equiv), inductor shall be dipped in a melted solder bath at 245 ± 5°C, 5 ± 0.5 seconds |

| Resistance to Soldering Heat | Appearance: No damage | Pre-heating: 150°C, 1min. Solder Temperature: 260 ± 5°C Immersion Time: 10 ± 1 seconds |

| Vibration | Appearance: No damage L change: within ± 10% Q change: within ± 30% DCR: within specification |

Test device shall be soldered on the substrate Oscillation Frequency: 10 to 55 to 10Hz for 1 min. Amplitude: 1.5 mm Time: 2 hrs for each axis (X, Y & Z), total 6 hrs |

Climatic Test

| Item | Requirement | Test Method | |||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Temperature Cycle | Appearance: No damage L change: within ± 10% Q change: within ± 30% DCR: within specification |

One cycle:

Total: 100 cycles |

|||||||||||||||

| Damp Heat with Load | Temperature: 40 ± 2°C Relative Humidity: 90 ~ 95% Time: 1000 hrs Measured after exposure in the room condition for 24 hrs |

||||||||||||||||

| High Temperature Storage | Temperature: 85 ± 3°C Applied Current: Rated Current Time: 1000 hrs Measured after exposure in the room condition for 24 hrs |

||||||||||||||||

| Low Temperature Storage | Temperature: -25 ± 3°C Time: 1000 hrs Measured after exposure in the room condition for 24 hrs |

☑ Storage Temperature: 15 ~ 28°C; Humidity < 80%RH

☑ Operating Temperature Range: -40 ~ +85°C

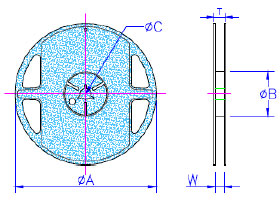

Packaging Quantity & Reel Specifications (Unit : mm)

| Type | Ø A | Ø B | Ø C | W | T | Quantity (EA) |  |

|---|---|---|---|---|---|---|---|

| NL03 | 178 ± 2.0 | 60 ± 0.5 | 13 ± 0.3 | 9 ± 0.3 | 12 ± 1.0 | 4000 | |

| NL05 | 178 ± 2.0 | 60 ± 0.5 | 13 ± 0.3 | 9 ± 0.3 | 12 ± 1.0 | 2000 | |

| NL08 | 178 ± 2.0 | 60 ± 0.5 | 13 ± 0.3 | 9 ± 0.3 | 12 ± 1.0 | 2000 | |

| NL10 | 178 ± 2.0 | 60 ± 0.5 | 13 ± 0.3 | 9 ± 0.3 | 12 ± 1.0 | 2000 | |

| NL12 | 178 ± 2.0 | 80 ± 0.5 | 13 ± 0.3 | 13.2 ± 0.3 | 16 ± 1.0 | 500 | |

| NL20 | 330 ± 2.0 | 100 ± 0.5 | 13 ± 0.3 | 17.4 ± 0.3 | 22 ± 1.0 | 1000 |

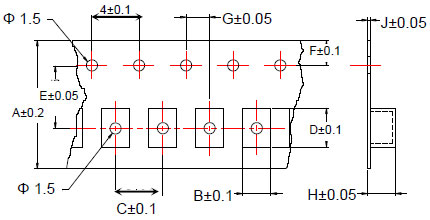

Embossed Plastic Tape Specifications (Unit : mm)

| Type | A | B | C | D | E | F | G | H | J |

|---|---|---|---|---|---|---|---|---|---|

| NL03 | 8 | 1.25 | 4 | 1.90 | 3.5 | 1.75 | 2 | 1.00 | 0.23 |

| NL05 | 8 | 1.85 | 4 | 2.55 | 3.5 | 1.75 | 2 | 1.45 | 0.23 |

| NL08 | 8 | 2.80 | 4 | 2.95 | 3.5 | 1.75 | 2 | 2.22 | 0.23 |

| NL10 | 8 | 2.96 | 4 | 3.60 | 3.5 | 1.75 | 2 | 2.40 | 0.23 |

| NL12 | 12 | 3.30 | 8 | 5.00 | 5.5 | 1.75 | 2 | 3.50 | 0.30 |

| NL20 | 16 | 5.35 | 12 | 6.10 | 7.5 | 1.75 | 2 | 5.50 | 0.35 |

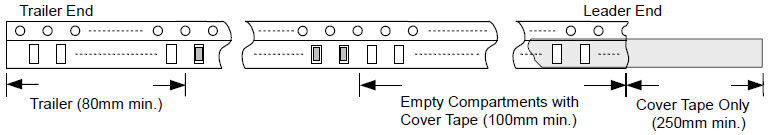

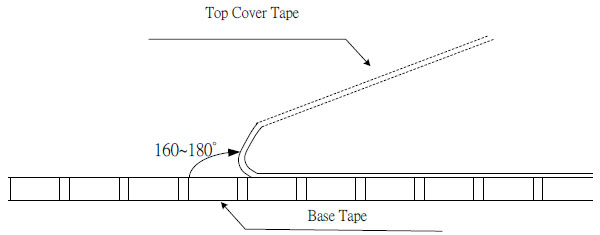

Leader / Trailer Tape

Cover Tape Peel Strength

The force for tearing off cover tape is 0.1 ~ 0.6 (N) in the arrow direction at the following conditions:

Thin film Precision resistor 0.01%, TC2ppm, wirebondale, Anti-Crossive, MELF. Current sensing, Metal...

Read More

Ceramic high frequency chip inductors, small size to 01005. Thin film, multilayer, wirewound , ferrite...

Read More

Multilayer Ceramic capacitor offers high Voltage, high frequency, low noise, High Q, Low TCR. NPO, X7R,...

Read More