AUTOMOTIVE APPLICATIONS

Thin film Precision resistor 0.01%, TC2ppm, wirebondale, Anti-Crossive, MELF. Current sensing, Metal...

Read MoreOur company aims at sustainable operation. Through the implementation of the existing supplier management system, we require suppliers to cooperate, follow relevant regulations on environmental protection, occupational safety and health, labor human rights and other issues, and jointly practice corporate social responsibility to create sustainable value.

Our company's supplier management policy is as follows:

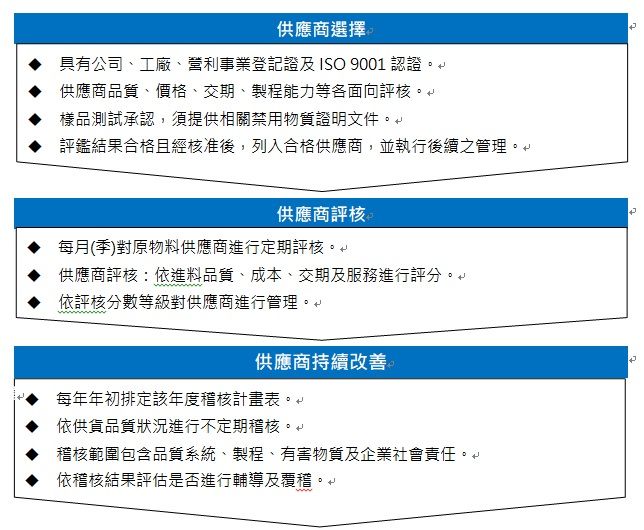

In order to establish a long-term and stable partnership with suppliers, Viking Technology has established a "supplier management procedure" in the hope that through clear management and operation methods, the supplier's delivery time, quality, technology and hazardous substances can meet Viking's expectations and customer needs.Viking's manages and guides raw material suppliers according to the following three stages.

1.Written evaluation:During the written assessment, suppliers must complete the supplier questionnaire and provide ISO 9001 quality management system certification for Viking's assessment and review.

2.Sample testing: When new suppliers are conducting sample approval, they must provide a "Safety Data Sheet (SDS)" and "Prohibited Substance Certificate (a third-party notary unit testing certificate document)".

3.Audit evaluation: After the supplier returns the quality system evaluation form, Viking convenes relevant departments to form an audit team to audit the supplier's quality system and production process to ensure that the quality of the products provided by the supplier meets the requirements of Viking and customers.

In order to obtain information on the quality and delivery of raw materials in real time, Viking evaluates the main raw material suppliers approved by the company on a monthly (quarterly/half-year) basis to avoid external uncertainties and risks that may impact operations or production. The evaluation items include four indicators. In addition to deducting points for non-compliance, a scoring mechanism is also established to encourage suppliers to propose self-improvement. The four evaluation indicators are as follows:

1.Quality: Scoring for raw material quality, customer complaints, market returns, customer production interruptions, change notifications, and quality certification.

2.Cost: Scoring for whether the price reduction of raw materials meets the target.

3.Delivery: Manage delivery punctuality and coordination to avoid excessive transportation caused by suppliers due to production raw material delivery or other reasons; prevent improper purchase cost transfer, and ensure that suppliers can respond to emergencies when encountering natural disasters.

4.Service: Scoring is given based on the supplier's delivery of quality-related reports and support for urgent matters.

Perfect supply chain management is the key to providing customers with good service and stable quality. In this regard, Viking proposes an annual supplier audit plan at the beginning of each year, and records it in the supplier annual audit plan table for regular implementation. The audit scope includes quality systems, processes, control of hazardous substances and corporate social responsibility. The audit results are divided into four levels: A (excellent), B (qualified), C (conditionally qualified), and D (unqualified). Suppliers who fail to meet the requirements must propose improvement measures, and Viking will provide guidance and review as needed.

In recent years, corporate social responsibility has become a crucial issue for companies pursuing sustainable operations. To mitigate the potential impact of supply chain risks on corporate operations, Viking Technology developed the "Supplier Social Responsibility (SA8000)/RBA/Integrity Commitment" and "Supplier Social Responsibility Survey" in 2017, introducing a supplier management mechanism. Going forward, we will continue to strengthen supplier risk management and work with our business partners to fulfill our corporate citizenship responsibilities.

Thin film Precision resistor 0.01%, TC2ppm, wirebondale, Anti-Crossive, MELF. Current sensing, Metal...

Read More

Ceramic high frequency chip inductors, small size to 01005. Thin film, multilayer, wirewound , ferrite...

Read More

Multilayer Ceramic capacitor offers high Voltage, high frequency, low noise, High Q, Low TCR. NPO, X7R,...

Read More